- Home

- Companies

- Process Engineered Water Equipment ...

- Products

- PEWE DeWater - Model DBP - Belt Filter ...

PEWE DeWater - Model DBP -Belt Filter Press System

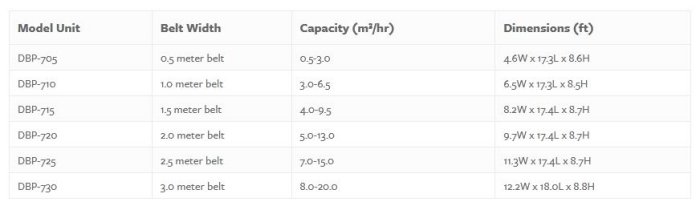

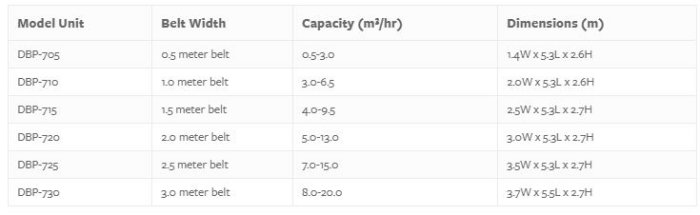

The unique technologies built into each PEWE DeWater DBP Belt Filter Press is designed to maximize solids recovery while minimizing chemistry usage during sludge dewatering. Selection of the appropriate belt press system depends upon the sludge solids encountered. DeWater DBP Systems come with an array of belt options to meet your specific solids requirements. Each belt filter press has a wide solids loading range and can accommodate future plant process changes, higher throughput or cake dryness requirements. DeWater DBP Systems are designed in a wide range of sizes which are suitable for both small and large sludge dewatering process applications. Tell us your requirements and PEWE can recommend a solution to match your specific needs. PEWE products and systems are designed in-house and produced under tight quality control.

- Twin Gravity DeWatering Zones-

- Improves efficiency prior to solids entering wedge zone.

- Produce a drier high solids cake.

- Graduated Pressure Process-

- Solids enter wedge under low pressure, meet increasing mid and then final high pressure.

- Maximizes shearing force with steadily increasing compression

- High Tech Powder Coated Roller Assembly-

- Anti-abrasion non-corroding roller surface improves static friction between the rollers and belts.

- Perforated rollers increase moisture removal.

- Adjustable Air Glide® System-

- Unique air cushion belt tensioner applies seamless pressure on each belt extending their service life.

- Variable frequency drive allows for maximum flexibility.

- Large Filtration Capacities

- Maximize Performance

- Sustainable Solids Feed Rates

- High Solids Capture

- Compact Footprint

- Triple Belt Wash System

- Easy of Maintenance