- Home

- Companies

- Dragon Water Technologies Ltd (DWT)

- Products

- PolyBlend - Model M Series - Polymer ...

PolyBlend - Model M Series -Polymer Feed System

The PolyBlend M Series liquid polymer feed system is the best product available to handle your liquid/solid separation needs. The M Series combines proven motorized mixing technology with precise controls to provide superior polymer preparation. In addition, the M Series can be configured with a variety of pump offerings, variable speed mixing and automatic dosage control with constant solution strength to meet a wide range of polymer feed application requirements.

The M Series units are also available for classified area environments including Class 1, Division 1 and Class 1, Division 2 areas. The M Series is engineered for quick easy service and is built to last. The open frame design permits quick and easy maintenance and the M Series is engineered to handle the harshest environments.

The M Series is designed to handle new polymer developments, ultra-high molecular weights, different charge densities, and even totally new chemistries. A constant speed motor is standard on the M Series and optional variable speed drives are available to accommodate application or technology. Optional advanced controls provide precise and consistent solution strength. Whether you adjust the M Series output remotely via 4-20 mA signal or right at the unit, water flow and polymer feed increase or decrease together. Primary and secondary dilution water are also kept at the same ratio as the output is adjusted.

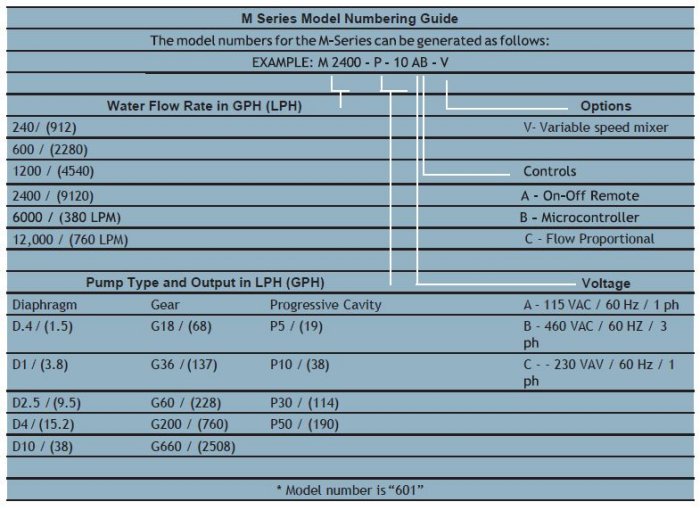

A variety of models are available covering output ranges from 0.1 to 200 USGPM (0.4 to 757.9 LPM). Choose between diaphragm, gear, or progressive cavity polymer pumps for your application.

- Improved polymer efficiency providing maximum polymer activation

- Open-frame design for easy access

- Reliable and consistent direct drive mixing

- Optional advanced controls to meet your application needs

- Power: 115 VAC / 60 Hz / 1 Phase / 10A

- Dimensions (W x H x D) : 685.8 x 673.1 x 228.6 mm

- 27” x 26.5” x 9”

- Polymer pump: Electronic Metering

- Material: 304 SS Frame / PVC

- Controls: Microprocessor-based REM-1E

- Connections: Water In: 12.7 mm (F) NPT (1/2”)

- Discharge: 19.05 mm (F)NPT (3/4”)

- Polymer: 12.7 mm (F)NPT (1/2”)

- Base Assembly

- Solenoid Valve

- Static Mixer

- Primary Dilution Control Valve

- Secondary Dilution Control Valve

- Mix Chamber

- Motor Control Panel

- Micro-Controller

- Pump, Progressive Cavity

- Pump, Priming Port

- Water Inlet

- Solution Discharge

- Polymer Inlet

- Pressure Gauge (Mix Chamber)

- Primary Dilution Water Sensor

- Secondary Dilution Water Sensor

- Operators Instructions