- Home

- Companies

- EMC Hycal Limited

- Products

- EMC Hycal - Model Mini Mk3 - Portable ...

EMC Hycal - Model Mini Mk3 -Portable Hydrogen Analyser for Molten Aluminium

The Hycal Mini Mk3 portable analyser provides rapid, accurate measurement of hydrogen dissolved in molten aluminium and its alloys.

The Hycal Mini Mk3 compact analyser can be used to:

- Perform spot measurements to check melt hydrogen levels prior to casting

- Continuously monitor dissolved hydrogen levels

- Monitor a melt treatment to achieve a desired hydrogen level e.g. degassing

- Monitor the dissolved hydrogen in a Low Pressure Die Casting furnace

The probe provides simultaneous measurement of dissolved hydrogen and temperature. Hydrogen sensing is achieved by an electrochemical hydrogen sensor located in the probe tip.

Calibration is assured through individual calibration of each sensor in a precisely controlled hydrogen atmosphere, and through testing of each probe prior to shipment. The analyser is a battery powered lightweight unit built with ease of use in mind.

The analyser automatically detects when the probe signal has stabilised. The analyser can store up to 5 days of continuously logged data.

Sophisticated On-Board Diagnostics (OBD) continuously monitor the condition of the probe and inform the operator if a problem is detected, ensuring reliable measurements.

Portable Design

- Designed for portable use with integrated carry case

- Internal Li-ion battery (11 hours depending on screen brightness)

- Integrated probe arm for portable measurements

Advanced Interface

- HMI interface

- Screen protector for industrial environments

- Vandal resistant push buttons

Comprehensive Diagnostics

- Analyser checks for any issues and shows an alarm if necessary

- Probe impedance monitoring within defined limits

- Gas pressure & flow monitoring

Data Management

- USB data transfer capability

- Front USB port for data transfer & HMI software updates

- Note: No digital comms (PLC / SCADA)

Internal Cylinder

- High pressure gas inlet

- Needle valve for precise control

- Pressure gauge (internal cylinder)

- Purge port to empty internal tank for transit

Connectivity

- Front USB port (data transfer / HMI software updates)

- Service USB port (alloy file, firmware updates)

- Ethernet port (automated calibration)

- Probe connection port

The maintenance panel provides easy access to internal service connections, allowing authorized personnel to perform calibration, firmware updates, and system diagnostics. All service ports are clearly labeled and protected for reliable operation in industrial environments.

Mains power

- IEC socket in lid

- Single phase

- AC 85 - 265 V, 47 - 63 Hz

- Charges Li-ion battery (8h)

Purge gas

- Nitrogen or argon

- Internal cylinder (~30 measurements)

- Gas purity same as used for degassing

- X-CAL: H2 gas mixture (e.g. 1% H2 in Ar)

Component: Description

- HYC.AZR.MINI.DEV.876: Hycal Mini Analyser Mk3

- HYC.AZR.UNI.ACC.004: Hycal refilling accessory

- HYC.CBL.LEN.030.618: Probe cable (3m)

- HYC.AZR.UNI.SUB.1046: Hycal Mini Magnetic Probe Stand

- HYC.AZR.UNI.DEV.801: Probe simulator

- GEC.GAS.ADP.268: FGG 2B to 6/4 Tube Adaptor Connector

- GEC.ECP.HWI.663: USB hub 4 port, USB powered

- Parameter: Specification

- Unit of measurement: ml/100g [@ 20°C and 1 atm] (milliliter of hydrogen per 100 grams of liquid aluminium )

- Sensor type: Electrochemical. Solid-state reference

- Reproducibility: ±0.01 ml/100g

- Response time: Initial result: 5 minutes typically. Subsequent reading: every 2 seconds

- Temperature of operation: 650°C to 800°C

- Analyser: 360mm x 300mm x 170mm / 10.5 kg

- Probe: Standard length: 800mm. Maximum depth of immersion: 300mm Diameter: 6mm

- Probe cable (std): 3000mm

- Refillable gas bottle (300ml): N/A - Probe Adaptor required

- Thermocouple: Type K

- Power supply (external unit): AC 85 - 265 V, 47 - 63 Hz

- Typical power consumption: < 8W

- Max. power consumption: 210W

- Battery chemistry: Lithium polymer

- Battery life: 11 hours (depending on screen brightness)

- Screen lighting: LED (white on black background)

- Screen resolution: 800 x 480 TFT colour LCD

- Screen size: 5" (125mm) diagonal

- Screen type: LCD graphical display

- Operating Temperature: 0 - 50 deg C

- Humidity: 5-95% non-condensing

Hycal Mini Mk3 uses the same probes as the rest of the Hycal product range. Therefore, with the correct measurement strategy (i.e. purge time / pressure / depth of measurement etc) identical results should be achieved.

However, Hycal Mini Mk3 does not offer the following:

- digital comms – no alarm outputs

- purge pressure / flow rate signals

- impedance diagnostics – to monitor the condition of the probe

- real-time graphical display

It is therefore not as easy to diagnose problems when they arise.

Hycal Mini Mk3 is the ideal choice for a quick spot check measurement as a replacement for density index measurements such as directly in the ladle, immediately after a degassing treatment.

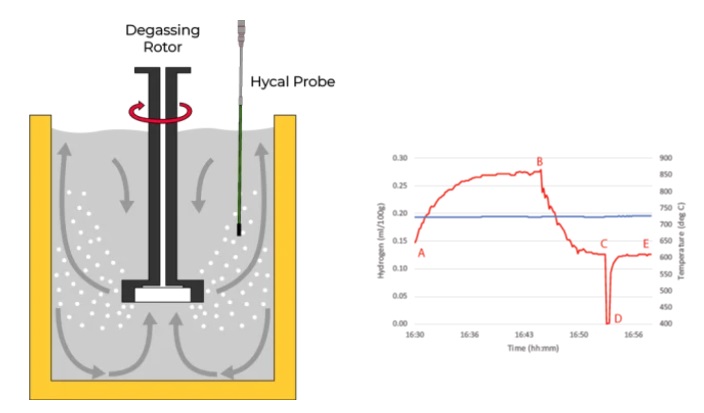

Hydrogen control during degassing

The graph below shows a `gassing-up` process followed by degassing treatment, verified finally by a static measurement.

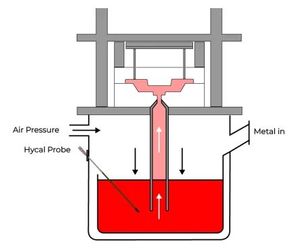

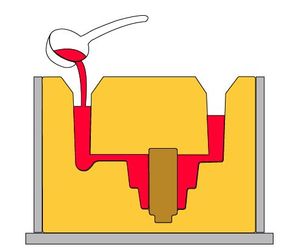

A Low Pressure Die Casting (LPDC) furnace has the additional complexity of being a sealed environment so that air pressure can be applied to force the aluminium up the riser tube into the mould above.

Hycal is unique in its ability to measure permanently in this environment by sealing to a custom flange plate with a compression fitting.

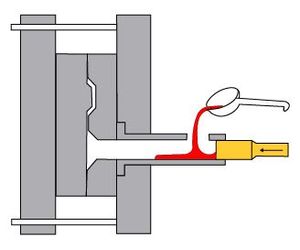

High Pressure Die Casting (HPDC) is generally thought not to suffer the same level of issues with hydrogen porosity compared to other castings methods. However, it remains necessary to control the hydrogen level as it can still have an influence of the mechanical properties such as tensile strength.

Hycal is unique in its ability to measure permanently in real-time within the degassing furnace, transfer ladle and also at the holding well at the HPDC furnace

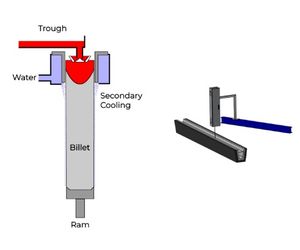

Hycal Probe Actuator located above the trough immediately prior to the casting table allows full automation and enables the entire cast to be monitored for dissolved hydrogen.

Measuring hydrogen content in the process of gravity casting aluminum is paramount to ensuring the quality and integrity of the final product. Hydrogen, when present in excessive amounts, can lead to severe defects like porosity and gas-related defects in castings.

These defects compromise the structural integrity, mechanical properties, and overall performance of the aluminum component, potentially leading to catastrophic failures in critical applications. By accurately measuring and controlling the hydrogen content throughout the casting process, manufacturers can mitigate these risks, enhance the material`s properties, and produce high-quality aluminum castings that meet stringent industry standards.

This precision not only ensures the safety and reliability of the final product but also plays a pivotal role in reducing waste and optimizing production efficiency, making hydrogen content measurement an indispensable aspect of gravity casting aluminum.

Typically, the hydrogen content of the aluminium would be measured during or just after the degassing treatment or at the holding furnace immediately prior to casting. However, due to the speed at which Hycal is able to reach equilibrium, it is also uniquely possible for Hycal to measure the hydrogen content directly within the mould itself, thereby providing a dissolved hydrogen measurement for an individual casting.

The ability to control hydrogen content in the aluminium is unique to Hycal for the following reasons:

- Hycal responds in real-time (within seconds once initial equilibrium has been reached).

- The guided degassing process can be used to program a hydrogen setpoint which will send a signal to the degassing machine telling it when to start / stop.

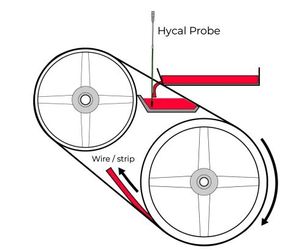

The measurement and control of hydrogen during continuous casting operations such as wire production is a critical part of the process.

Hydrogen related defects may compromise the structural integrity, mechanical properties, and electrical properties, potentially leading to catastrophic failures in critical applications. By accurately measuring and controlling the hydrogen content throughout the casting process, manufacturers can mitigate these risks, enhance the material`s properties, and produce high-quality aluminum castings that meet stringent industry standards.