- Home

- Companies

- ProSep Inc

- Products

- ProSep - Model CTour - Process Removes ...

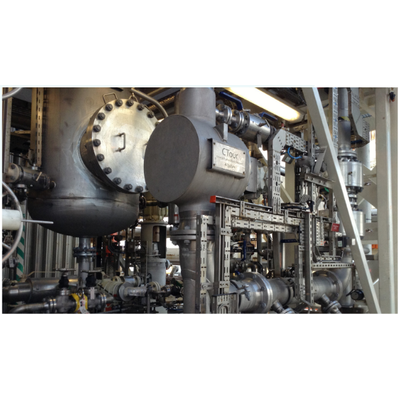

ProSep - Model CTour -Process Removes Dispersed Oil and Dissolved Hydrocarbon Contaminants System

The CTour process removes dispersed oil and dissolved hydrocarbon contaminants in the produced water stream through injection of condensate.

HOW CTOUR WORKS:

During the injection of condensate through ProSep’s proprietary inline injection and mixing technology, the residual hydrocarbons coalesce with the condensate to form larger and less dense droplets. These oil droplets are hydraulically or mechanically separated from the produced water stream by downstream separation equipment, and the hydrocarbons are recovered back into the applicable process stream.

TREATMENT LEVELS:

The CTour process routinely yields residual oil discharges of < 5 ppm total petroleum hydrocarbons (TPH), while at the same time removing 80-95% of harmful water soluble organics, such as polycyclic aromatic hydrocarbons (PAH) and BTEX (benzene, toluene, ethyl-benzene and xylene) components. The CTour process is used extensively in Norway, having treated as much as 70% of all Norwegian offshore produced water. This equates to more than 2 million barrels of water per day.

- Performance – Removes OIW to below 4-5 ppm

- Reduces dissolved hydrocarbons (PAH, phenols, BTEX) by 80 – 95%

- No waste products – no disposal/transportation costs

- No chemicals added

- Easy to install in existing systems

- Very low operating costs

- Robust process, low maintenance

- Removal of < 5 micron oil droplets

- Removal down to 14 API crude