- Home

- Companies

- Wood Waste Control (Eng) Limited

- Products

- Wood Waste Contror - Single Shaft ...

Wood Waste Contror - Single Shaft Shredders

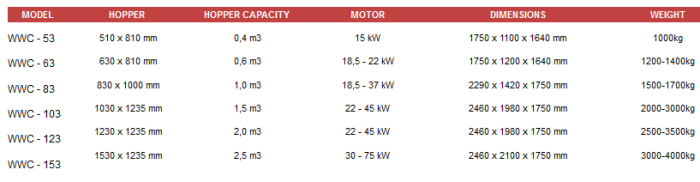

Single Shaft Shredders to shred (almost) everything! Our range of shredders are designed to shred all kinds of waste material, including hard and soft woods, chipboards, OSB and plywood panels, as well as construction timber.

We can also tailor the shredder to deal with other materials such as Papers, cardboards and metals and rubber.

Manufactured in Germany, with proven robust construction and reliability.

These shredders can be shipped with many different options to suit customer requirements such as different screen sizes, hoppers and an extra row of knives.

All shredders are fitted with an automatic stop when the hopper is empty.

WWC - Shredders in more detail

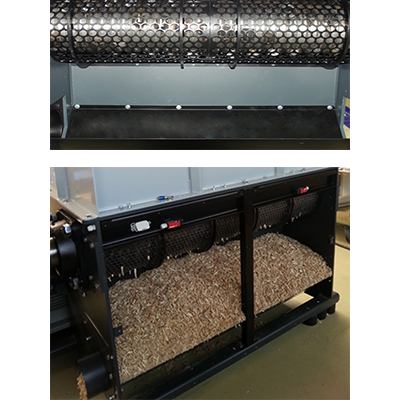

WWC Shredders are fitted with a slowly rotating profile solid steel rotor (260 or 360mm Dia) which is mounted on the sturdy machine base. The knives are available in various designs for all kinds of material. These knives feature a low wear and can be rotated several times before they eventually need to be replaced.

The screen is made of heavy welded construction, with the screen size determining the size of the chips. Screens with different hole sizes for all kinds of material are available.

The main rotor is driven by a V-belt drive and a spur gear with torque support.

The material to be shredis filled into the hopper, the Siemens PLC determines the optimal feeding rate depending on the power input from the main motor. Thereby the highest possible throughput can be realised. After reaching the front position the hydraulic slider drives back with fast hydraulic into starting position the cycle restarts. The shredding occurs in-between the rotor and the fixed counter-knife.

The slider can be fitted with wipers in order to prevent materials from jamming the pusher. The chips can be delivered out of the machine by means of suction or conveyor screw.

Once the material is shredded completely the machine turns off automatically. WWC shredders are fitted with dust-tight control cabinet for the PLC control. These machines are manufactured in Germany and have been CE-certified.

- Fast Hydraulic- Profile Rotor.- Second Row of Knives- Control cabinet with Siemens PLC- Automatic stop when hopper empty.- Removable exhausting channel- Performance enhancing pacing of hydraulic sliders