- Home

- Companies

- Spire Metering Technology, LLC.

- Products

- Spire Metering - Model EF40 - ...

Spire Metering - Model EF40 -Wall-Mount Ultrasonic Flowmeter

A member of the EnduroFlow Series, the EF40 Ultrasonic Flowmeter is the first member of the 4th generation ultrasonic flow meters from Spire Metering. Compared with its predecessors, the 4th generation flowmeters feature advanced multi-frequency flow measurement technology, thus, offering wider pipe size coverage, better accuracy and richer features. The EF40 ultrasonic flowmeter is designed to be installed at a fixed location for long-term flow measurement on a closed pipe, carrying pure liquids or liquids with some suspended particles. EF40 can be equipped with clamp-on or wetted (insertion or flow-cell) type transducers to meet various application challenges.

Signal Quality Tracking

EF40 flowmeter utilizes cutting-edgetechnologies such as advanced transducer design, low voltage transmission, digital signal processing, self adaptation, and more, to achieve high performance. Its proprietary quality tracking mechanism analyzes the quality of the received signal and automatically tunes the meter system to its optimized condition. This mechanism leads the system to be easily adaptable to pipe material variations and liquid property changes.

Multi-frequency

EF40 main unit can be programmed to operate at 0.5MHz, 1MHz or 2MHz frequency. Together with transducers of compatible frequency, EF40 is able to measure flow on pipes from DN20 (3/4”) up toDN3000 (120”) with various pipe materials.

Transducer Pairing and Wetted Calibration

As QUALITY is of crucial importance, all transducers are carefully paired, and all flowmeters are wet-calibrated on the flow loop in the factory to further ensure the system accuracy and reliability.

Thermal Energy Measurement

With a pair of RTD temperature probes and a thermal energy module, EF40 can measure the thermal energy (BTU) as well as the temperature of the supply and return lines of a heating / cooling circuit.

EF40 provides versatile input/output interfaces, such as digital and relay outputs, batch control, alarm and flow/energy totalizing, 4-20mA output, RS485/Modbus and optional BACnet output, which can be easily used by a host computer, BMS, PLC or a flow controller for process monitoring and control.

Non-intrusive. Non-obstructive

With clamp-on transducers, the installation becomes very simple and easy. No pipe work is required and there is no risk of leaking or contamination. With wetted transducers, there is no obstruction to the flow, thus, there is no pressure drop.

Economical to Operate, Economical to Own

The ultrasonic transducers are made from crystal. There are no moving parts to wear and tear. The whole meter system is completely solid state. Therefore, EF40 is a robust and reliable system. It does not require maintenance or downtime which eliminates any potential incurred costs.

- No moving parts to wear and tear. No maintenance required

- NIST-traceable factory calibration

- Multi-frequency system. Able to work reliably in a widepipe size range

- Able to measure thermal energy and temperature with BTU measurement option

- Suitable for pure liquids and liquids with some particles. No dependency on conductivity

Compatible with various types of transducers:

- Clamp-on transducer: non-contact, non-invasive, easy and economical installation, no pipe working

- Insertion transducer: robust, excellent long-term stability, hot-tapping installation, no need to shut down the flow

- Flow-cell transducer: most accurate and robust. Plug and play. Excellent long-term performance

- Large storage data logger for recording flow, temperature, status, and more

- Communication: RS485/MODBUS. Optional BACnet/ MSTP, GPRS, RF wireless

- IP65 protection

- Water/Wastewater

- Hot/Chilled Water/Mixture of Water and Glycol in HVAC systems

- Chemical Liquids and Solvents

- Petroleum Products

- Oil/Crude Oil/Fuel Oil/Diesel/Lubricant Oil/Hydraulic Oil

- Water management in buildings, metropolitans, water/ wastewater treatment plants, irrigation systems, and more

- Suitable for pure liquids and liquids with some particles. No dependency on conductivity

- Flow monitoring and control in desalination plants, steel plants, power plants, machining plants, pump stations

- Liquid process control in chemical plants and industrial automation

- Retrofit capability, to upgrade or augment existing systems

- Automated batching and scheduling

- Efficiency monitoring and improvement of liquid-based heating/cooling systems, including solar/geothermal systems

- Beverage, food and pharmaceutical processors where non-contact is essential

The EnduroFlowTM Series flowmeters are based on the transit-time measurement principle. The system utilizes a pair of sensors (A and B in figure below) that function as both ultrasonic transmitter and receiver. The sensors are installed on the pipe wall, either clamped on the outside of the pipe or inserted into pipe at a specific distance from each other, and the flow meter operates by alternately transmitting and receiving a coded burst of sound energy between the two sensors and measuring the transit time it takes for sound to travel between the two sensors. The difference in the transit time is directly related to the velocity of the liquid in the pipe. The flowrate is then calculated based on the transit-time difference, the geometry of the pipe and the fluid dynamics formula.

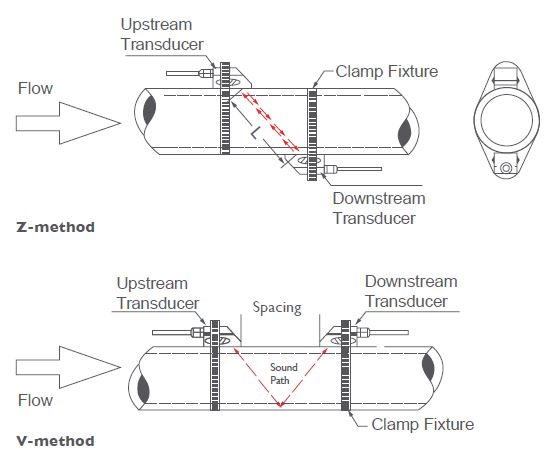

The sensors are commonly mounted with the Z-method or the V-method. With the Z-method, the two sensors are installed on the opposite side of a pipe. This method offers shorter sound path, thus, better signal strength. It is often used for large size pipes where signal strength is more important. With the V-method, the two sensors are installed on the same side of the pipe. The sound path is doubled, and as a result, the measurement accuracy is better. This method is often used for small and medium size pipes.

For insertion and flow-cell type transducers, however, only the Z-method is used.

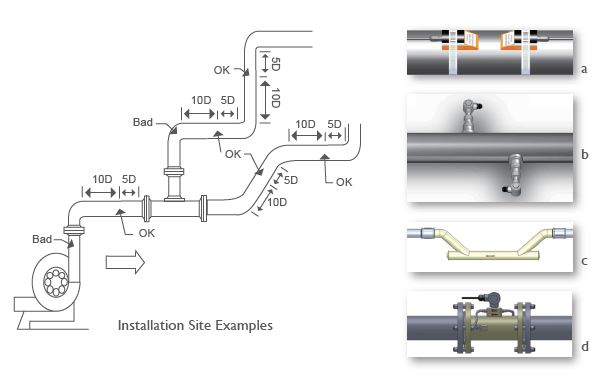

The four figures below illustrate how the transducers are installed on a pipe. The clamp-on transducer (figure a) is mounted on the outside of a pipe with a mounting fixture using the V-method. The insertion transducer (figure b) is hot-tapped or cold tapped onto the pipe using the Z-method. The flow-cell (spool-piece) transducer comes in two varieties: for size DN40 (1 ½”) or smaller, PI-type transducer (figure c) is used, where its pipe joint could be threaded or flanged. For size DN50 (2”) or larger, the transducer is a standard spool-piece with two ultrasonic sensors installed using the Z-method (figure d) where it is normally connected to a pipe line using a flange connection.

The site of the transducer installation is very important. Here are some recommendations for selecting the right site:

- In order to achieve good accuracy, it is recommended to have 15D straight-pipe run: upstream 10D and downstream 5D, where D is pipe diameter.

- If there is a valve upstream and the valve is not fully open, it could generate flow disturbance. A longer upstream straight pipe is recommended.

- If there is a pump upstream, we recommend to have 25D straight pipe run.

- If the pipe is vertical, make sure the flow is going upward, not downward. Downward flow could have air gaps if the flow is free fall.

- If the pipe is horizontal, make sure the pipe is full! The transducers should be installed on the side of the pipe, not on the top or bottom of the pipe.

- Flow Velocity: ± 10 m/s (± 32 ft/s). Bi-directional

- Accuracy: ±1% of reading ±0.008m/s (±0.03ft/s) in velocity*

- Repeatability: 0.2%

- Response Time: 3s. Configurable between 3s and 99s

- Display/ Keypad: LCD widi backlight 2 x 20 letters. 4x4 tactile-feedback membrane keypad. Displays instantaneous flow rate, flow total (positive, negative and net), velocity, time, temperature, energy, analog outputs/inputs

- Units: English (U.S.) or metric

- Physical Quantity: Volumetric flow rate, total flow, velocity, analog inputs, temperature, energy rate, energy total

- Totalizers: Positive totalizer, negative totalizer, net totalizer, daily totalizer, monthly totalizer, yearly totalizer, manual totalizer, energy totalizer

- Security: Keypad can be locked with password

- Outputs:

- Current Output:

- 0/4-20mA isolated output for flowrate, velocity or sound speed. Impedance 0-Ik.Accuracy 0.1%

- Digital Output:

- Optically isolated OCT (Open Collector Transistor) output Up to 0.5A load. Can be programmed as:

- Pulse signal for flow totalization

- ON/OFF signal for special event such as overflow, no flow, reverse flow, leakage alarming, and more

- START/STOP signal for batch control

- Can be used to drive pulse counter, external relay, alarm, PLC counter

- Relay Output:

- 1 A@125VAC or 2A@30VDC Can be programmed as: Pulse signal for flow totalization

- ON/OFF signal for special event such as overflow, no flow, reverse flow, leakage alarming, and more

- START/STOP signal for batch contro

- Can be used to drive pulse counter, external relay, alarm, PLC counter, or,to control pump, valve, light

- Sound Alarm: One sound alarm, programmable to specific event such as overflow, no flow, reverse flow, leakage alarm

- Inputs:

- One 4-20mA input for temperature, pressure or liquid level transmitter

- Two temperature channels for accommodating two PT100 4-wire temperature sensors.This function is only available upon request

- Recording: Automatically records die daily total of the last 64 days, the monthly total of the last 64 months and the yearly total of the last 5 years

- Communication Interface:

- Isolated RS-485 with power surge protection. Supports die MODBUS protocol

- Optional RF/GPRS module for wireless networking, remote monitoring and remote control

- Optional BACnet/MSTP adapter for BMS

- Software: Optional StufManager PC software for real-time data acquisition and remote meter control (applicable for RS485 output only)

- Telemetry**: uGalaxy_GPRS wireless telemetry systems are available upon request

- Enclosure:

- Protection: IP65

- Dimensions: 280mm x 220mm x 90mm (11" x 8.66" x 3.54")

- Features: Weather-proof Aluminum, power coded

- Weight: 3kg (6.62lbs)

- Environment Temp: 60°C (140°F)

- Power sources: 12-24 VDC, 90-260 VAC 50/60 Hz <2W@12VDC

Notes:

* Under reference condition and velocity should be above 0.5ft/s. Flowrate is calculated by multiplying velocity with the inner cross-section area of the pipe.

** For wireless telemetry system solution, please contact solutions@spiremt.com.