CCC VorSpin - Stainless Steel Vorspin Hydrocyclones

The VorSpin Hydrocyclone Series utilizes centrifugal separation principles for efficient removal or classification of suspended solids in slurries. These hydrocyclones are designed with three key features to enhance performance: a Volute feed inlet that minimizes undesirable turbulence, a Fluted Vortex Finder that accelerates separation by increasing slurry momentum, and a Non-plugging discharge Apex that prevents blockage via a differential pressure region. The stainless steel construction ensures durability and resistance to abrasion, making these hydrocyclones suitable for applications such as sand and silt removal, drilling fluids solids removal, and catalyst removal. Engineers and project managers in various industries value these hydrocyclones for their simplicity and absence of moving parts, which translates to lower maintenance requirements. The VorSpin Hydrocyclones are available in both stainless steel and high-density urethane to meet diverse operational needs.

The VorSpin Hydrocyclone Series: Hydrocyclone applications have a wide appeal to engineers and project managers in many industries because of their designed simplicity with no moving parts. The Fields of Industry applications are shown below:

- Food and Beverage

- Chemical

- Pharma

- Refineries

- Petrochemical

- Breweries

- Distilleries

Some specific applications: Sand and silt removal or separation, drilling fluids solids removal, catalyst removal and soil washing.

Hydrocyclones use the centrifugal separation principle to remove or classify suspended solids in a slurry.

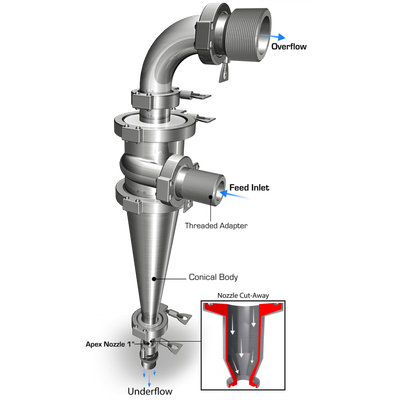

The VorSpin Hydrocyclone features three improvements in hydrocyclone efficiency:

- A volute feed inlet

- A fluted Vortex Finder

- A non-plugging discharge Apex

The Volute feed inlet prevents the slurry from circulating back into the path of the incoming slurry, causing undesirable turbulence that reduces separation efficiency.

The Fluted Vortex Finder shape increases the momentum as the incoming slurry swirls around the increasing cross-sectional area, causing a more rapid separation of the suspended solids. This also prevents larger particles from “short circuiting” and reporting out the Vortex Finder with the liquid phase and smaller particles.

The Non-plugging discharge Apex has a non-circular orifice configuration with a central core and lobes surrounding the central core. As the solids report out the Apex discharge, the surrounding lobes will cause any central core plugging to wash through by producing a differential pressure region.