Toro Equipment S.L.

- Home

- Companies

- Toro Equipment S.L.

- Products

- Defender - Static Screens

Defender - Static Screens

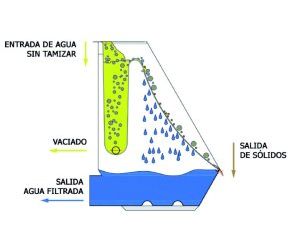

Its mission is to eliminate the solids carried by the water, in order to avoid clogging and mechanical problems in the installations. This equipment requires little maintenance and operates continuously, without the need for electricity. In urban waters, they can replace primary decanters in many cases, providing the elimination of coarse sands and up to 30% percentages of grease and effluent leftovers. Spans of 0.50 to 0.15 millimetres are used. From 30m³/h up to 228 m³/h.

Most popular related searches

rotary screen

safety system

static screening

urban water

static screen

liquid filter

drum filter

finishing scraper

screen filter

mesh filter

Perforated

- Mesh size from 2 to 3 mm Ø

Grid

- Mesh size from 0.15 to 2mm

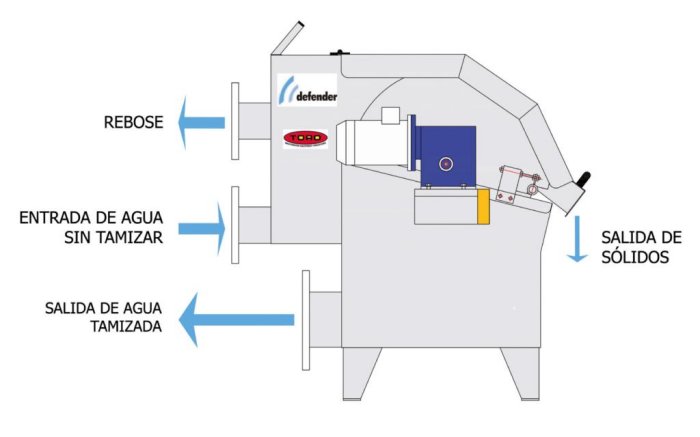

- The effluent to be treated enters through the flange on the outside of the screen body and is evenly distributed through the spillway and overflow through the filtering drum.

- The solids are retained on the surface of the drum while it is rotating, the spill penetrates through the mesh opening and performs a self-cleaning function by passing through the lower part of the drum again.

- As it passes through the outer scraper, the solids are released from the screen and gravity causes the solids to fall off the scraper.

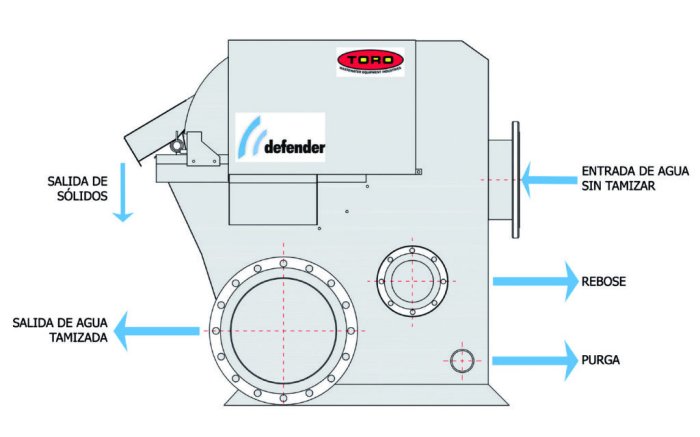

- The effluent to be treated is pumped or pressurised to the screen head.

After a certain retention time, determined by the filling of the screen’s feed box, a laminar overflow occurs in which the liquid slides smoothly through the filter mesh. - In this sliding process, the liquid passes through the screen (most of it in the first section), with the solids retained on the screen surface and falling to the bottom and draining out of the screen. and out of the screen. The filtered liquid falls into the lower tank The filtered liquid falls into the lower tank and is evacuated by gravity through a pipe.

- By means of a lifting structure, it is possible to install the equipment can be installed at the head of the plant, so that it can move on to the next stage of the treatment stage without the need for pumping.

- Safe designs with high quality materials

- Manufactured in 316 L stainless steel.

- GRP components and protections.

- Incorporates effective safety system.

- GRP flanges with DIN/ANSI connection.

- Pressurised water cleaning system for the filtering drum.

- Shot blasted finish.

- Solids scraper adjustment

- Paper industries

- Foods

- Wineries

- Dairy

- Meat

- Canneries

- Fish

- High oil content

- Laundry

- Biodiesel

- Tanneries and textiles

- Urban