- Home

- Companies

- Sono-Tek Corporation

- Products

- SonoFlux - Model 2000F - Stationary ...

SonoFlux - Model 2000F -Stationary Ultrasonic Spray Fluxing System

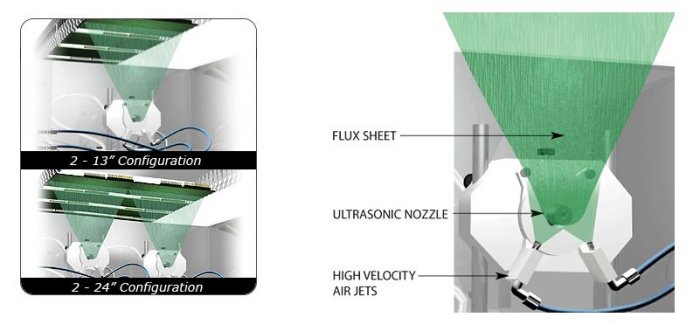

Stationary ultrasonic spray fluxing system for low mix/dedicated lines with medium to high volume. No moving parts mean ultra-low maintenance and the highest reliability and is compatible in all major wave solder machines. All SonoFlux systems feature non-clogging, repeatable, low maintenance ultrasonic spray performance with up to 80% reduction in flux consumption.

- SPRAY ASSEMBLY DIMENSIONS:

- 330mm (13”) configuration – 514.4mm W X 330.3mm L x 193.5mm H (20.25” W x 13” L x 7.62” H) or 610mm (24”) configuration – 514.4mm W X 610mm L x 193.5mm H (20.25” W x 24” L x 7.62” H)

- PCB WIDTH RANGE: 50-330mm (2–13”) or 50-610mm (2-24”)

- CONTROL: Backlit LCD PLC with menu-driven 17-key keypad and wheel encoder

- FLUX DELIVERY: High precision gear pump

- POWER REQUIREMENTS:

- 110/120 VAC, 50/60 Hz or 220/240 VAC, 50/60 Hz

- Single phase, 750 VA max

- AIR: 483-1034 kPa (70-150 PSI) @ 85 LPM (3 CFM)

- CERTIFICATION: CE

- ULTRASONIC NOZZLE DESIGNS: High transfer dual jet design

- Only a monthly clean up, even with rosin flux

- High velocity flux transfer for maximum top-side fill

- Uniform coverage

- Reduction in flux consumption up to 80%

- Non-clogging ultrasonic design

- Elimination of thinner

- Easy operation and maintenance

- Compatibility with all fluxes

- Deposition density control micrograms/inch

- Single or dual nozzle configurations available

The 2000F is designed with a high transfer efficiency spray assembly and a closed spray chamber, to capture any rosin flux vapor in the environment.The system can either be installed internally in your wave solder machine, or can be available as a stand-alone unit, both with a variety of optional features.

Low maintenance and no operator intervention, are the primary features of the SonoFlux 2000F. Only a monthly cleaning is necessary (even with sticky rosin flux).

The system is also equipped with a high velocity flux transfer system, to help with PCBs that have difficulty with topside fill, such as those with thick back planes, tight lead-to-hole ratios, or contaminated components.