- Home

- Companies

- TCR-Tecora

- Products

- Isokinetic Heated Rotative Probe - TCR ...

Isokinetic Heated Rotative Probe - TCR Tecora

More and more standards forced stack emission testers to adapt their equipment and the necessary devices to carry out correct pollutants sampling activity. Cooling-condensed molecules presence in the exhausts makes it necessary to heat the probe and all the connected devices. All the materials used therefore have to guarantee stability to processes and ensure resistance to high temperatures and corrosive gases. To meet these requirements, TCR Tecora® developed a new heated isokinetic probe and placed it on the market, born from the needs of customers to face new scenarios in emission sampling.

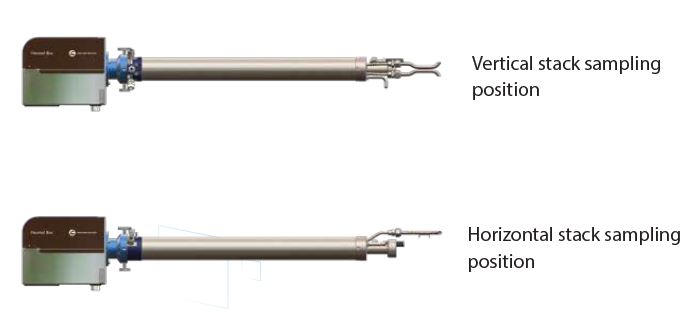

A mechanical joint allows the rotation of the sampling tube to fit to non-vertical ducts or to perform swirl angle checks during verifications imposed by ISO 16911 standard.

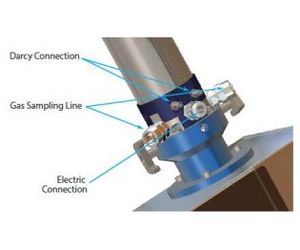

- 360° rotation into flange;

- 360° rotation of filter box around probe;

- 3 sampling lines (1 main + 2 auxiliary) with sampling dedicated line;

- Total insulation of the heating element and thermocouple from the stack gases;

- Built-in AISI 316 stainless steel;

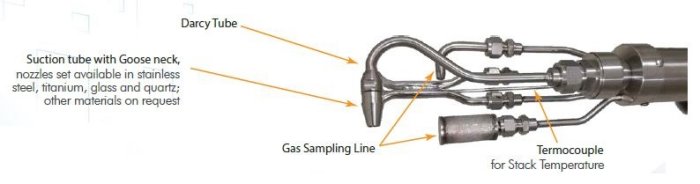

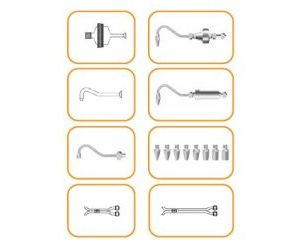

- Interchangeable suction lines (stainless steel, glass titanium and quartz);

- Compatible with all TCR Tecora® devices, either in-stack and out-stack (filter holder, Pitot tubes, impactors, refrigerant systems, dioxin kits etc.);

- Compliance to international standards EN and US-EPA (EN 13284-1, ISO 16911, US EPA M5, ISO 9096 etc);

- Facilitate manipulations without disconnecting the impingers and the bath (compl. ISO 16911-1);

- Easy testing of all types of stacks (vertical, horizontal).

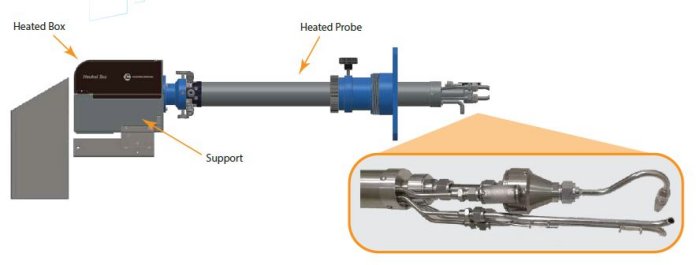

The probe is composed of 3 main elements:

- Heated Probe;

- Heated box for filter and filter holder;

- Support with handles for box and probe that allows the connection of other devices (dioxin trap, impingers bath and other devices).

1) External protection tube in AISI 316L stainless steel which acts as a "supporting structure". The design features adopted have made it watertight, preventing entry of gas from the outside.

Internal coaxial heated tube, also in AISI 316L stainless steel, heated by a cylindrical stainless steel heating element, equal in length to its extension. This allows the homogeneous heat distribution over the entire surface and assures that the gas is actually heated to the requests conditions. Calibration with temperature meters primary standard are carried out during functional testing. A type K thermocouple inserted on a stainless steel support and in contact with the tube is used as measuring element of the heat emitted by the heating resistance.

The adjustment takes place via Isoterm (electronic device with PID regulators and SSR relay) or via Isostack G4 automatic sampler.

2) Sampling tube, inserted inside the hated tube. This is the real step of sample suction. All the materials used compliance with reference regulations relating to the types of pollutants requested to sample: it must be ensured that they do not react chemically absorbing a part or altering the composition.

Available: AISI 316L stainless steel, titanium, glass borosilicate and quartz.

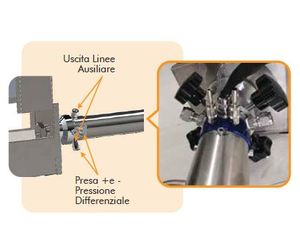

3) Auxiliary sampling lines. In the same area where the heating resistance acts were two internal 4mm diameter AISI 316L stainless steel tubes inserted, useful to extract gas to be sampled (moisture, VOCs and other parameters content) or analyze through continuous analyzers (TOC, SO2, NOX, CO and others)

4) Flow measurement. Inside the principal tube, lines of differential pressure measured by the Darcy Tube are installed at the front of the probe via tight metallic fittings.

The probe length varies from a minimum of 0.5 mt to a maximum of 3 mt. Other lengths are taylored made.

As integral part of the probe, this device allows particulates sampling with the use of a filter holder (47 mm or 90 mm) or thimble holder installed outside. This is mandatory if the characteristics of the process (gas with condensate in suspension or condensing due to low temperature, ex. Low boiling VOCs).

For this purpose it is also necessary to heat the box:

160°C (230Vac – 200W).

180°C (120Vac – 400W).

The box consists of a thick stainless steel casing capable to resist to possible mechanical shocks due to impacts during transport. A special insulating material that covers the internal surface part, decreases heat exchange with the outside, preventing the metal surface from becoming dangerous for contact burns.

Internal volume is heated by a pair of steel armored stainless steel heating elements dividing inside heating. A type K thermocouple inserted on a stainless steel support and exposed inside the box, is used as an element of measurement of the heat emitted by the armored resistance. Regulation occurs through ISOTERM (electronic device with PID regulators e SSR relay) or via ISOSTACK G4 automatic sampler.

Traps support is an essential part of the isokinetic probe. It enables to:

- Ensure the 360° rotation of the box around probe axis;

- Fix the several traps (impingers bath, dioxin kit…) to the probe;

- Make the manipulation of the whole heated probe easier.

Optional:

Flange for probe sliding and putting inside the stack with sliding bushing system, in order to facilitate handling of the probe during measurement grid checks (e.g. EN 15259, EN 16911-1, EN 13284-1).