- Home

- Companies

- Tekran Instruments Corporation

- Products

- Tekran - Model 3300Xi Series - Mercury ...

Tekran - Model 3300Xi Series -Mercury CEM Electric Generating Unit

The Tekran Series 3300Xi Mercury CEM is in place at over 130 sources in the U.S. For every installation, we have met and exceeded all performance requirements for our customer’s state and federal regulations. Tekran® is the most experienced mercury monitoring resource in the world and continues to lead in mercury compliance monitoring, abatement system control and mobile testing systems.

Tekran® is continuing to support and provide new Model 3300Xi individual components and systems to our North America industrial customers. Our 3300Xi system provide all of the capabilities necessary to meet and exceed the regulatory requirements for mercury emission monitoring.

In reliability, system availability and analytical accuracy, the Tekran® Series 3300Xi systems have outperformed all competitors in EPA and private tests in wet and dry stacks. The Series 3300Xi can measure total, elemental and ionic mercury in virtually any combustion source. The system is sensitive enough to measure levels at any coal fired power plant or other industrial emissions source, and is immune to the interferences that plague conventional mercury CEMs.

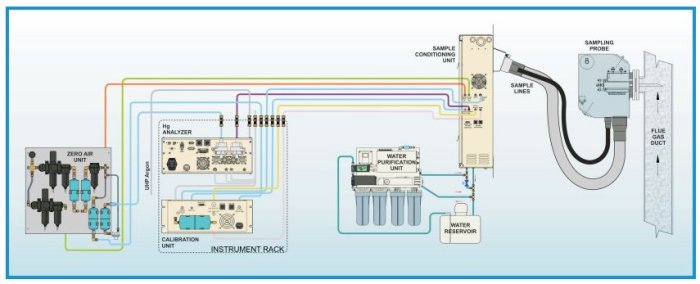

Typical System Components

- Tekran® 3321 Wall Mounted Sample Conditioner

- Tekran® 2537Xi Continuous Mercury Vapor Analyzer

- Tekran® 3310Xi Elemental Mercury Calibration Source

- Tekran® 1304 Air Filtration System

- Tekran® 1308 Recirculating Water Conditioning System

USA Mercury Regulation Activity

The EPA Electric Generating Unit Mercury and Air Toxics Standards (EGU MATS) and Portland Cement

Maximum Achievable Control Technology (PC MACT) regulations require reductions in gaseous mercury emissions. Tekran has proven technology to support mercury compliance monitoring, abatement system optimization, and performance audit testing instrumentation.

Air Pollution Control Equipment: Performance Guarantees andAcceptance Testing

Architect engineers, consultants, and end users are seeking validation of mercury abatement technologies

including, but not limited to:

- Pre-combustion chemical additives

- Post-combustion treatment

- Mercury oxidizing technologies

- Wet scrubber additives

- Custom mist eliminators

Current specifications requiring performance guarantees face difficulties due to:

- Inlet/outlet conditions that are ill-defined

- Sorbent trap systems may over estimate gaseous Hg

Tekran is the only company to provide all the following:

- Ten years of HgCEM system design, manufacture, service, and support

- Multi-point HgCEM sampling technology for inlet/outlet testing

- NIST Traceability – Tekran 3310Xi low and high level generators used by NIST

- Low-level measurements certifications of accuracy (EPRI, EERC, CATM, ICCI)

- Service personnel averaging 10,000 hours of field and laboratory experience

- Parts, training, and support by phone, email and remote access

- Patented mercury speciation technology to determine elemental, ionic and total mercury

- Unaffected by SO2, NOX, CO, HCl and all other common combustion by-products

- Interfering acid gases removed without chemical reagents or solid sorbents

- Provides real-time feedback for mercury control technology optimization

- Detection limit of 0.01 ug/m3 as determined by EERC/ICCI independent study

- Low-cost calibration eliminates expensive mercury calibration gas cylinders

- No chemical reagents required

Electronics Platform

- Network enabled

- Touch screen interface

- Local data storage and front panel USB port

- Remote access (troubleshooting, control and configuration)

- Improved data and instrument parameter logging

- Additional functionality via optional s/w plugins (std. additions, remote valve control, and much more)

Detector

- New lamp stabilizer and detector electronics

- Easy cuvette removal via convenient fitting interface

- Improved stability and sensitivity

- Digital PMT control and display

Permeation Source

- Lower dead volume permeation chamber

- Digital permeation source set point and display

- Improved accessability

Cartridge / Valve Assembly

- New low dead volume valve assembly

- Constant power heater control

- Faster cartridge cool down with individual high-velocity fans

Physical Layout

- Reduced height from 5U (8.75”) to 4U (7”)

- Improved component accessibility for routine maintenance