- Home

- Companies

- Terra Systems, Inc. (TSI)

- Products

- Terra Systems SRS - Model SD - Small ...

Terra Systems SRS - Model SD -Small Droplet Emulsified Vegetable Oil Substrate

Terra Systems patented "injection ready" 60% SRS®-SD Small Droplet Emulsified Vegetable Oil Substrate is added to the groundwater to rapidly generate reducing conditions and provide the necessary carbon and hydrogen to support native or introduced microorganisms (Dehalococcoides) for the biodegradation of chlorinated solvents such as tetrachloroethene (PCE) and trichloroethene (TCE) to innocuous end products including ethene and ethane.

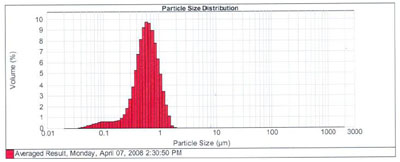

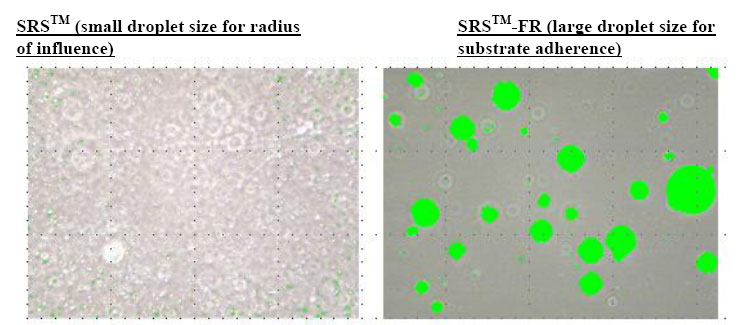

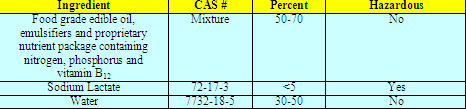

- The 0.6 um droplet size results in better substrate distribution for the client, easier substrate injectability for the driller and fewer injection points for the consultant thereby lowering costs Provides 73% fermentable carbon Has >98% biobased content Includes sodium or potassium lactate to kick-start the anaerobic degradation process, nutrients and Vitamin B12 a micronutrient, which He et al. 2007 demonstrated is an important micronutrient to enhance dechlorination activity.

- The nonionic emulsifier (does not have a charge) results in better distribution and bacteria contact for the client because the substrate does not readily stick to the positively charged soil particles.

- It arrives as a homogenous injection ready substrate, which results in lower field labor costs from inefficient field mixing.

- Proven effective with PCE, TCE, TECA, DNAPL (Sabre Project), Perchlorate, TCA, Cr6+, TNT, Uranium and Nitrate. Proven effective at military installations (Andrews AFB, Dover AFB, Beale AFB, Ft. Gillem, Fort Dix, Camp Bullis, Aberdeen Proving Ground, etc.), dry cleaners, semiconductor manufacturers, fabricators and manufacturing firms that use and clean metal parts (air conditioners, dishwashers, etc.).

- Promotes biodegradation of PCE and TCE to non-toxic end products

- Small droplet size is ideal for maximum radius of influence in the formation

- Low cost

- In situ vs. Ex situ application minimizes site disruptions

- Slow release formula eliminates continuous substrate additions

- SRS™ contains only non-toxic food grade materials, which results in green, sustainable remediation

- Can be used as a PRB to cuts off plume migration

- Effective in source zones

- Reduces treatment time from decades to months and years

As a result of its low viscosity, small droplet size and longevity, SRS™ is an ideal substrate for injection using direct-push technology. The low viscosity allows a greater volume of SRS™ to be applied in a shorter period of time and increases the substrate delivery radius per point. This results in fewer direct push delivery points and overall shorter delivery time requirements per site.

Terra Systems, Inc. has applied this technology at military bases, dry cleaners and manufacturing sites throughout the USA and in Brazil and Japan. Some of the sites where the technology has been demonstrated include the Dover Air Force Base (AFB) in Delaware, Columbus AFB in Mississippi, Camp Bullis in Texas, Altus AFB in Oklahoma, Arnold AFB in Tennessee, Edwards AFB in California, Photocircuits in NY, SABRE in England and Microtronics in New Jersey.