KRACHT GmbH

KRACHT - Model KF 3/100...KF 6/730 -Transfer Gear Pumps

FromKRACHT GmbH

Centrifuge construction, Coating machines, Compressors. Engine construction. Filling stations, Filter systems. Generator construction. Heat transfer systems, Heavy electrical machines.Lubricant manufacturers, Lubricating oil systems. Machine-building industry. Machine tools, Manufacture of apparatus, Marine engine construction, Metal-forming machines, Metering systems. Paint industry, Plain metal bearing production, Printing machines, PUR machinery. Refrigerators, Rubber and tire manufacturing. Tank plant construction, Transmission building Turbine construction. Vacuum machinery. Waste oil - disposal, transport, treatment.

Most popular related searches

gear pump

pressure relief valve

relief valve

rotary shaft seal

waste oil disposal

waste oil

pump pressure relief valve

oil waste

flanged pump

printing system

- Adhcsivcs, Antifreeze

- Bore oils

- Cutting oils

- Diesel oils, Drawing compound

- Emulsions

- Fuel oils, L, EL, H

- Gear oils. Grease

- Hardening oils. Heat transfer media, Heavy oils. Hydraulic fluids

- Isocyanate

- Lubricating oils, Lacquers

- Motor oils

- Paint, Paraffins, Plastics, Polyols Printing inks. Processing oils

- Resins, Rolling oils

- Waste oils, Waxes

- KF gear pumps are used for pumping a wide variety of fluids.

- KF gear pumps are distinguished especially by their wide range of variants which arc assembled as required on the modular principle and also permit subsequent upgrade.

- The pumps are also suitable for media with low lubricating properties.

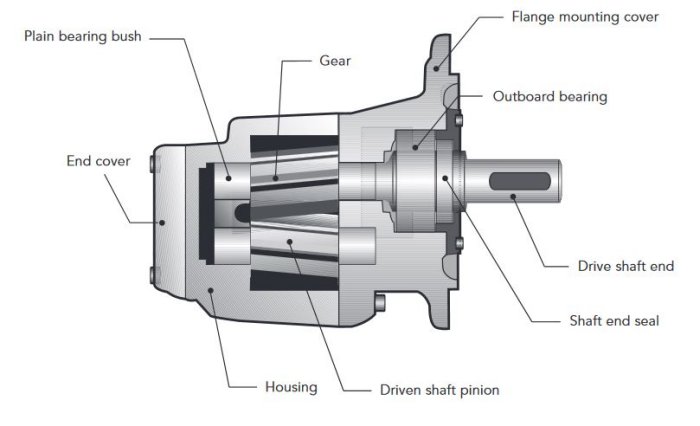

- The standard housing sections are of grey cast iron. The gear units are manufactured from high strength case hardening steel, hardened and mounted in special multicompound plain bearing bushes.

- The standard drive shaft is sealed by rotary shaft lip type seal.

- All pump sizes incorporate helical tooth system. This feature, combined with special gear geometry, results in extremely low noise levels and reduced pressure pulsation.

- The fluids should ensure a certain minimum lubricating properties, should not contain solids and should be chemically compatible.

- Avoid dry operation.

- The pumps may only be operated in the specified direction of rotation, as otherwise the shaft seal will be destroyed.

- In order to prevent excessive overpressure, a safety valve should be provided in the system or on the pump.

- The pressure relief valve attached to the pump may only be used as safety valve for short-term operation.

- A separate pressure relief valve with return line to the reservoir must be foreseen, if a partial discharge flow has to be drained over a prolonged period.

- Sealing of the drive shaft:

- Rotary shaft lip-type seal

- Double rotary shaft lip-type seal (Quench)

- Mechanical seal

- Outboard bearing to take up input drive-side radial load

- Pressure relief valve for pump and system

- Uniform discharge flow direction with changing direction of rotation by means of flange-mounting valve combination (universal device).

- To meet your individual requirements on request special constructions are available: for instance mounting flange models, various types of plane bearings, etc.

- Our Sales engineers will be pleased to advise you.

- Connecting flange

- 4-bolt type

- Mounting angles

- Pressure relief valves (attachable subsequently)

- Foot mounting flanges for the adaptor flanges below

- Base plates

- Couplings

- Adaptor flanges (pump carrier)