- Home

- Companies

- Trelleborg Forsheda Pipe Seals

- Products

- Trelleborg - Model 560 Rieber IPS - ...

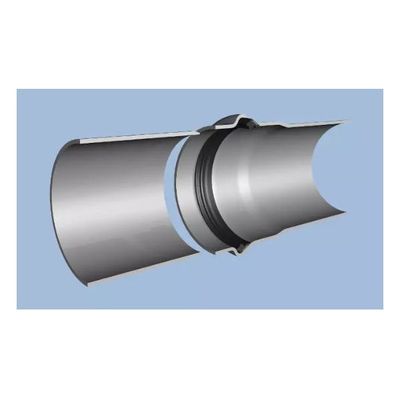

Trelleborg - Model 560 Rieber IPS -Integrated Sealing System for Plastic Pressure Pipes

Forsheda 560 Rieber IPS integrated system uses the mandrel together with the seal as a tool to form the pipe socket during the manufacturing process. Forsheda 560 Rieber IPS is a seal composite consisting of: A flexible rubber element to seal effectively against spigot and socket. A treated metal insert which holds the seal firmly in place. The seal is placed onto the socket during pipe manufacture, ensuring it is always in the correct position in the join. The seal is equally effective under both positive and negative pipe pressure (vacuum).

- Cannot be displaced during transportation & installation

- Greater joint reliability due to joint tolerance reduction

- Traditional Rieber style seal for IPS pipes

All data in inches.

On each seal, profile thickness, outer diameter, recommended pipe measurement and production period are given. The corresponding data are also on the packaging.

Subject to change for technical reasons

The spigot and socket of the pipe should be checked for damage prior to jointing.

The pipe spigot should be chamfered with an angle of 15°, taking care to remove all burrs. Both spigot and socket including the sealing ring should be free from dirt and other foreign matter.

Lubricant should be applied evenly to the spigot end of the pipe.

Immediately after lubrication, the spigot should be brought into contact with the socket.

Both spigot and socket should correctly aligned and then slide the spigot into the socket, thus compressing the seal until the joint is fully made.