Trucent - Industrial Centrifuge Systems

Custom Industrial Filter Solutions & High-Performance Automatic Disc Stack Centrifuges. Given enough time, gravity will always separate fluids of different densities. Oil and water form their own layers, and particles are drawn together and either float to the top or settle at the bottom. You can see it when you look at the different layers formed in a bottle of Italian dressing that’s been left sitting undisturbed.

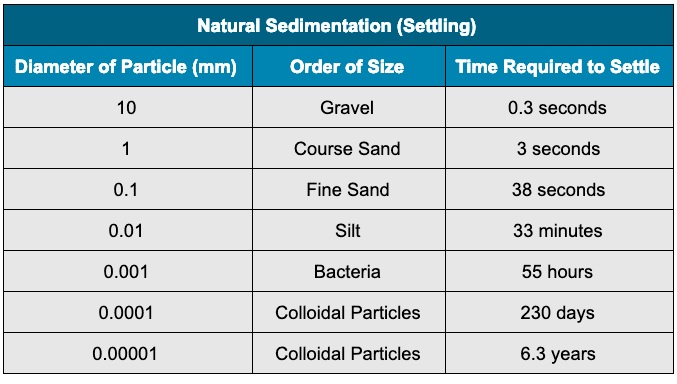

But it takes time: Fine sand or silt will settle out of suspension in under an hour. Colloidal particles can take years.

Centrifugation is this exact same process, but highly accelerated. This gives us control over various aspects of that separation: How long it takes, how accurately various materials are separated from each other, and how the captured water, oil, chemicals, sludge, slurry, and particles are routed from there.

In many applications, industrial centrifuges and decanters have proven to be the most effective methods of separating and filtering oil, water, and suspended solids. Depending on your application, that can translate into long-lasting (and cleaner) coolant, increased tool life and product quality, decreased maintenance and downtime, or new revenue streams. But the bottom line is always the same: lowered costs and improved ROI.

Trucent provides a wide variety of centrifugal separators that have been designed for liquid-liquid, liquid-solid, and liquid-liquid-solid separation (i.e., “3-phase separation”).

Over the last 20 years, we’ve combined this technology with existing barrier-based and non-media separator technology—as well as new fundamental research into fluid analytics, chemistry, and purification strategies—to craft custom solutions for a wide range of industries. These include metalworking and manufacturing (stainless steel, aluminum, etc.), utilities and wastewater, glass grinding, biotech and pharmaceuticals, food and beverage, ethanol and biodiesel, waste oil and waste vegetable oil processing, agriculture, and more.

A centrifuge speeds up the natural sedimentation process by spinning materials at high speed, artificially generating a force thousands of times greater than gravity. That rotational speed, coupled with mechanically sound design, makes it possible to directly manipulate many factors that govern how commingled materials behave.

Trucent’s CentraSep DX Series centrifuge machines offer both two-phase and three-phase processing. (“Two-phase” is liquid-liquid separation, usually separating water-based and oil-based liquids or a liquid from a solid; “three-phase” refers to liquid-liquid-solid separation, which separates a water phase, oil phase, and solids.)

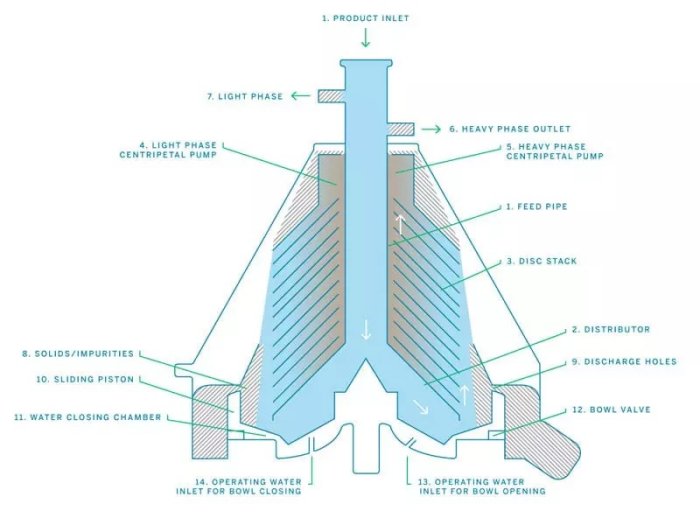

The separation takes place in the centrifuge’s bowl, which rotates at high speeds. The diagram above shows a three-phase (liquid-liquid-solid) centrifugal separation process. First, commingled water/oil/particulate flows into the bowl through a feed pipe (1) and into the distributor (2), where it is accelerated until it reaches the bowl’s rotating speed. It is then conveyed to the bowl (3) where the separation takes place. This bowl is divided by many thin discs (the so-called “disc stack”), which dramatically increases the unit’s separation efficiency. In water-based coolant applications, the “light phase” (usually tramp oil) flows toward the center of the bowl and leaves the disc assembly via its inner edge. The clean coolant (or “heavy phase”) flows toward the bowl periphery. The two liquid phases exit the bowl from separate points. Here, two centripetal pumps (4 and 5) convey each phase separately under pressure to its respective outlet port (6 and 7).

Simultaneously, the solid impurities (9) collect on the underside of the discs. They are continually forced to the periphery of the bowl (8), where they are periodically discharged automatically through the discharge holes. The discharged solids are collected into an outer annular chamber connected to a damping sludge tank, where they drain away through a pipe.

We’ve invested a great deal in centrifuges—but we do not limit ourselves to centrifuges. At Trucent, we’re dedicated to a process-oriented approach: We work with you to holistically understand your entire process so that we can find the right intervention, use the right technology, and match it to the right application.

In order to make the most of this approach, we’ve spent decades investing in a team composed of more than equipment experts and engineers. We bring together people who understand decanter centrifuges, separators, non-disposable media filtration, and other equipment and people who understand fluid separation at a fundamental level, in addition to being familiar with your fluids and your processes/industry.

And we can go one step further: Trucent can install a team in your plant to run and manage all your fluids and filtration technology on a daily basis. Your in-house Trucent team will handle fluid buying and filtration, monitor those fluids, and maintain your entire centrifuge systems and filter solution.

Service has been the backbone of our business for decades. If you already have a centrifuge, we can help you get more out of it. Trucent Centrifuge Parts and Repair will refurbish, repair, maintain, and program all makes and models of disc stack centrifuges. If you’re new to media-free filtration, we’re here to work with you and find the right solution, one that will work reliably over the long haul. Our team will get you up and running, train your team, and offer ongoing centrifuge parts, maintenance, and service packages.

No one else offers this level of comprehensive service with centrifuges.

Every solution begins with a conversation. Contact us today to begin that conversation or schedule a no-obligation on-site consultation. A Trucent engineer will “walk your process,” sampling your fluids pre-process, post-process, and at every important stage along the way. We’ll take samples back to our lab for analysis, and then design an oil purification/liquid separation system to meet your spec and your business goals. Every solution is pilot tested in our labs. If needed, we’ll run a no-obligation trial on-site as well.