- Home

- Companies

- Corgin Ltd.

- Products

- Corgin - Model T-series - Tube ...

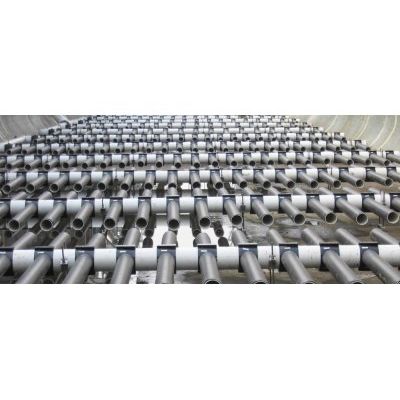

Corgin - Model T-series -Tube Diffusers

FlexAir T-Series Tube Diffusers are generally chosen in applications with high airflow requirements, and/or in harsh wastewater environments. They are available in liftable or fixed grid configurations and they are manufactured from high quality materials to suit all process operating conditions and wastewater types.

CHOICE OF MEMBRANES

T-Series Tube Diffusers have a premium quality EPDM rubber membrane sleeve, specially perforated for high volumetric air handling capacity and headloss efficiency. Alternative membrane materials such as polyurethane, silicone, and other specialty polymers are available for industrial and aggressive effluents. Several perforation patterns are available to suit efficiency and headloss needs. With a variety of diffusers, membranes and perforations to choose from, Corgin can help design your system to operate at maximum efficiency and peak performance.

These diffusers are available in 62mm and 91mm diameters and withlengths from 250mm to 1000mm to cover a wide range of flow rates and floor layouts. They are available as saddle mounted or threaded units.

FEATURES

- Pre-fabricated components

- Pre-assembled and quality tested

- Pipework system

- Height adjustable Stainless Steel pipe supports

- Integral condensate drain option

- Precision die cut openings

- High capacity membrane options avail able

- Triple check valve design

- Resistant to fouling and plugging

- ABS and PVC construction

- Non-buoyant design

- Mounts on any pipe material (PVC, ABS, CPVC, SS, etc.) or size

BENEFITS

- For rapid installation and ease of removal in the event of any

- maintenance

- Toensure air and water tightness, and that pressure loss is within an

- acceptable range

- To allow expansion and contraction with temperature changes and to

- reduce installation and removal costs

- For ease and speed of levelling during installation

- To provide reliable automatic condensate purge with no need for

- operator input

- High oxygen transfer, uniform air release, and low operating pressure

- Maximum airflow and low operating pressure

- Prevents entry of liquid/solids into piping. Ideal for on/off applications

- Low maintenance

- Maximum chemical, temperature, and UV resistance

- Reduced uplift and stress on mounting connection

- Economical capital cost and ease of installation