Armtec - Water Control Gates

Armtec is an industry leader in water control gates for wastewater treatment plants, water treatment plants, and irrigation and flood control projects. Thousands of customers globally can attest to the high quality of Armtec’s gate products.

Water control gates control the flow of water from point to point in open channel situations. We offer a variety of flap gates, sluice gates, slide gates, overshot gates, radial gates and roller gates to meet specific needs. Gate systems include manual or power operating systems, stems, accessories and, in some cases, automation packages for operating the gates.

- Premium quality

Available in cast iron, fabricated aluminum, fabricated stainless steel - Wide range of products, sizes and shapes

Includes flap gates, cast iron slide gates, fabricated aluminum and stainless steel slide gates, overshot gates, radial gates and roller gates - Custom design

Standard configurations and custom design available - Options

Manual and power operating systems, stems, accessories

- Water treatment plants

- Wastewater treatment plants

- Irrigation canals

- Flood control

- Small hydroelectric plants

- Industrial treatment facilities

“ Their knowledgeable representatives went to great lengths to ensure total project satisfaction.”

Durable end-finishes for drainage and stormwater systems

Durable

Made from precast concrete, composite reinforced polymer or steel sheeting

Versatile

Can be used with multiple pipe structures

Fast and easy installation

Prefabricated or easily constructed on-site

Combines the lightweight properties of plastic with the strength of concrete

Lightweight

Typically 10% of the weight of concrete headwalls, ideal for weak subgrades

Fast and easy installation

No grout system, easily moved by hand or on-site equipment

Environmental benefits

Fish-friendly, non-leaching materials

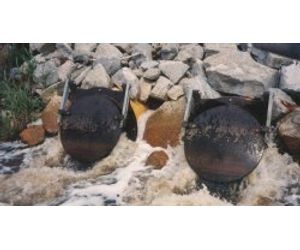

An environmental solution to enable fish to get upstream for spawning

Minimizes ecosystem disruptions

Used when urban development encroaches on the natural habitat

Wide range of lifting devices for water control gates

Variety

From handwheel lifts to electrically operated units with torque and limit switches or hydraulically actuated cylinders

Quality

Enclosed cast iron housings, mechanical seats, precisioncut gears, anti-friction ball or roller bearings

Easy and economical way to control flow in a channel

Easy to handle

Lightweight, aluminum, stainless steel or carbon steel construction

Stackable

Log heights in 152mm increments or custom heights, can be stacked for equipment isolation

Versatile sizing

Custom widths to suit project needs

Separate cast piece forms an opening in a wall structure for mounting gates

Simplifies gate installation

Thimble is positioned into the wall before the concrete is poured, eliminates need for cast-in-place anchor bolts

Minimizes distortion

Provides a rigid, accurate mounting surface for the gate

Easy gate removal

Gates can be easily removed and transferred for cleaning and painting

An economical way to divert water in rectangular channels

Corrosion resistant

Aluminum frame, slide and reinforcing components

Embedded and surfacemounted frames

Extruded metal section embeds in side walls or is mounted on the face of the rectangular flume or conduit

Large steel gates shut off water flow to permit emergency maintenance or equipment repairs

Tight leakage control

Rubber seals around the perimeter of the gate control leakage

Versatile

Can be used in multiple locations and removed completely for storage

Stackable

Stacking gates permits flow control for larger openings

Lightweight, economical gate designed for wide, unobstructed waterways

Minimal hoist effort required

Can be opened and closed with minimal effort

Quality construction

Consists of a curved gate leaf, rubber seals, support arms, seal rubbing embedments and embedded pivot points

Selection

Overflow and breastwall types available, wide range of sizes

Used to control flow in open channels and closed conduits

Compact design

Requires less than one-half of the overhead operating clearance needed for a slide gate

Easy to operate

90° turn to go from fully open to fully closed

Simple installation

Jack bolt mounting, can be installed after the channel is completed

Used for flow control in applications where water flows over the slide

Specialized application

Enables flow to be measured and ensures a constant upstream water elevation

Stainless steel

High corrosion and erosion resistance, can be made in many shapes

Self-adjusting seals

Provide low leakage rate and consistent sealing performance

Designed to control flow through large waterway openings

Quality construction

Consists of a fabricated steel slide with cast iron rollers and rubber seals

Minimum friction

Lower friction resistance in opening and closing than sliding surfaces

Versatile

Range of sizes, finishes, overflow or breastwall style

Designed for exceptional low leakage in corrosive environments

Stainless steel

Frame, slide, stem and fasteners are stainless steel type 304 and 316

Low leakage seal

Ultra-high molecular weight polymer molded seal provides low leakage and ensures smooth operation

Control water flow through openings for seating or unseating head

Precision seating face

Machined bronze or stainless surfaces provide a precision seating face, low leakage rate and consistent sealing performance

Range of openings

Square, rectangular and round flange openings available

Act as natural skimmers of debris such as branches, logs and trash

Open and close automatically

Allows discharge and prevents backflow without mechanical lifting devices

Double hinge action

Ensures proper seating of the flap against the frame

Adjustable top pivot points

Optimizes gate action and sealing

High-quality, cost-effective gates for low head applications

One-piece design

Consists of a flat-back cast iron seat, slide and crossbar, attached to a yoke

Robust cast iron

Resists warping, deflection under head and damage when closing on debris

Offer a simple way to prevent fluid from returning into pipes or openings

Corrosion resistant

Available in stainless steel and aluminum

Flat-back seats

Can be attached to wall thimbles, new concrete headwalls, existing walls or pipe flanges

Designed for low leakage requirements in corrosive environments

Rugged frame

Stainless steel type 304 or 316 frame

Water tight

Furnished with rubber seals to improve water tightness

Designed for use in openchannel flows where up-stream level control is required

Unique design

Includes bottom-hinged design that enables the gate to fully open

Environmentally friendly

Fish-friendly passage to migrate upstream