- Home

- Companies

- Henan Sinovo Machinery Engineering Co., ...

- Products

- SIMEC - Model MFSP140 Series - Wood ...

SIMEC - Model MFSP140 Series -Wood Hammer Mill

MFSP140 series wood hammer mill is designed to grind a variety of woody wastes and other biomasses with large sizes, such as wood chips, chopped barks & branches, shredded roots, wood blocks, chipped wood slabs, corn cob, chopped paddy straw and cotton stalk, shredded palm EFB fiber, shredded old palm trunk, sugarcane bagasse, and so on.

MFSP140 wood hammer mill adopts steel plate welded structure. Electric motor and milling rotor are installed on the same base and directly connected by coupling. The milling rotor is checked by high precision dynamic balance. The top-open feeding inlet matches with dilated feeding belt conveyor. The milling hammers are arranged symmetrically.

MSFP140 wood hammer mill features compact structure, high grinding efficiency, sturdy and durable production, safe and reliable operation and easy maintenance.

- SKF BEARINGS for milling rotor, including AUTOMATIC BEARING COOLING SYSTEM by circulating coolant liquid. Reduce maintain consumption but increase the service life of bearings.

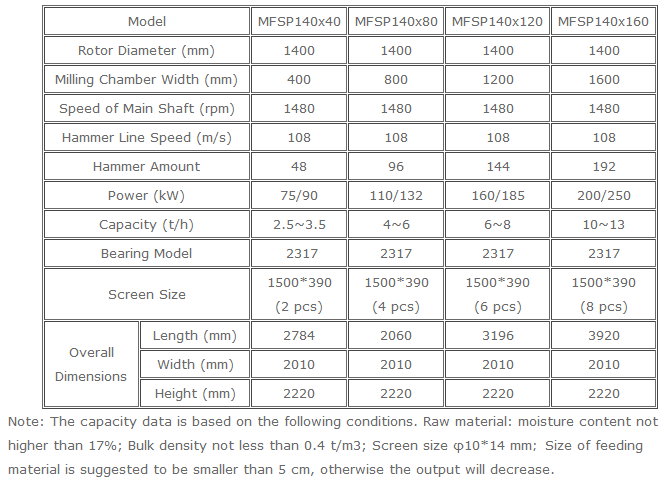

- SIEMENS standard motor. Multiple milling chamber design. DIAMETER 1400 MM milling rotor, WIDTH 400 to 1600 MM milling chamber.

- Specially designed multi stage material discharging system to ensure large output capacity and reduce power consumption;

- Reinforced and welded as a whole pedestal plus the uniquely designed damper results stable operation;

- Specially designed fast open slide gates to change screen and to inspect inside status;

- Double sound-proof layers on the slide gates lead to 90~95 decibel low operation noise;

- Ingeniously hammer fixing groove results quick hammer replacement;

- Split design reduces maintenance cost of screens;

- Milling rotor lifting device to benefit maintenance on bearings, hammers, etc.

- High efficient dust collection system ensures clean emission;