- Home

- Companies

- Nexus Solutions Inc

- Software

- Nexus - Version CEMView - Gas Auditor ...

Nexus - Version CEMView -Gas Auditor Software

CEMView Gas Auditor is a dynamic, configurable software application to automate the cylinder gas auditing and testing procedures. Complex and labor intensive regulatory compliance tests, such as a Cylinder Gas Audit (CGA) or a Linearity check, are initiated, controlled, recorded and reported with the CEMView Gas Auditor.

The application is designed to work in parallel with the CEMView Data Acquisition & Reporting Software or as a stand-alone application with direct connectivity to an instrument with an appropriate instrument OPC server. With the CEMView Gas Auditor, various cylinder gas checks can be pre-programmed and easily run, on demand. Automatic and / or manual control sequences are easily developed with the integrated Windows Scripting Languages (VB Script and JScript).

- CEMView Gas Auditor saves on your bottled gases by automatically proceeding to the next step (averaging) as soon as the reading is stabilized and near expected value is achieved.

- The potential for human errors are significantly reduced by eliminating the possibility of skipping a step, plumbing the wrong bottle, not applying each gas long enough or calculating results incorrectly, etc.

- Tests will automatically abort should response times, near expected values, or stability criteria not be met. This saves running an entire test and hand calculations to determine results.

- No need for personnel to change bottles.

- No need to manually calculate response times.

- Technician can walk away after initiating a test.

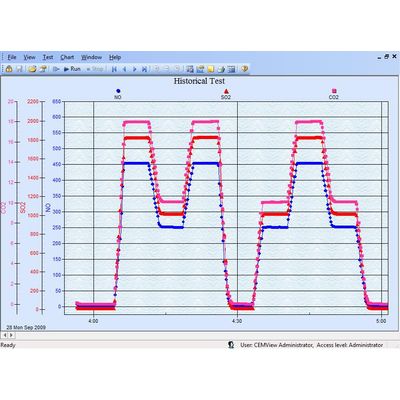

- Technician can watch live trend of a test in progress.

- Message box displays current step in progress.

- The expected values will change on the chart with each bottle.

- CGA/Linearity report is automatic. No need to manually enter data into a custom spreadsheet.

- The results of each CGA/Linearity test are permanently stored for easy retrieval at a later date.

- Typically 1-2 hours of work verses 4-8 hours of work for each CGA/Linearity test.

- CEMView Gas Auditor allows you to run a CGA/Linearity test on each source simultaneously saving a significant amount of time on multi-source systems (when each source has its own data buffer).

- New plant personnel can easily perform the CGA/Linearity testing since the details of sequencing the valves, retrieving the data and calculating results are automatically handled by CEMView Gas Auditor.

- Saves thousands of dollars every quarter outsourcing linearity tests.

For example, the following is done to configure a Cylinder Gas Audit test in Gas Auditor.

- Specify the gases to be audited.

- SO2, NO, CO2

- Specify the sequence for the test

- Low, High, Mid, High, Low, Mid, Low, High, Mid

- Configure purge time and averaging time for the sequence

The application’s built-in inventory management capabilities for the gas cylinders allows the tracking of the following information:

- Gas cylinder manufacturer name

- Cylinder serial number

- First used on date

- Cylinder expiry date

- Gases in the cylinder

- Concentration of each gas in the cylinder

Before a CGA test starts, the application will automatically check and generate warning alarms if:

- Gas cylinder is out-of-date

- Cylinder gas pressure is low

The application will then proceed if everything is okay and it will automatically control the appropriate solenoid valves to produce the pre-programmed timing and sequence as it was previously specified. At the end of the pre-programmed sequence, the application will compute the following:

- Average CEM response value for the three audit points for each gas

- Average CEM response value and the accuracy in percent, for each gas

- Pass / Fail based on the results of the test.

A Cylinder Gas Audit Data Assessment Report is then automatically generated for the test by the system.