- Home

- Companies

- Advanced Cyclone Systems, S. A. (ACS)

- Applications

- Emission control solutions for biomass ...

Emission control solutions for biomass and coal combustion sector - Energy - Bioenergy

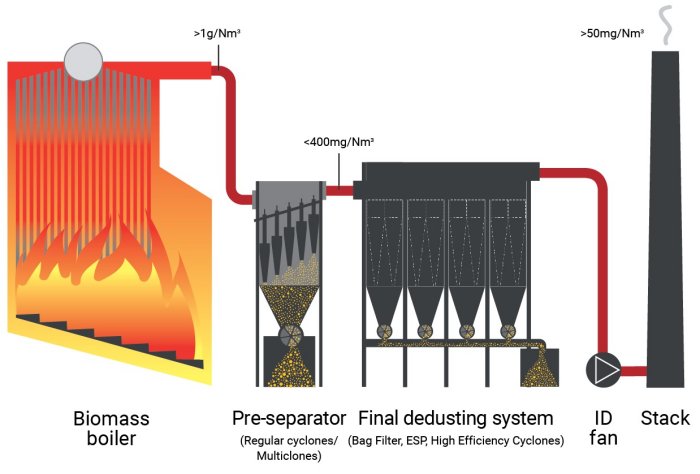

Burning biomass and or coal releases particulate matter (PM) to the atmosphere, polluting the surroundings and harming the human health. PM emissions is a common problem in industries that operate furnaces or boilers to generate heat or steam for their processes or for electricity generation to be sold to the grid. The general arrangement of a biomass or coal combustion plant includes a cyclone pre-separator to reduce the concentration of particles after the boiler and a final dedusting system.

Pre-separation is especially important to remove the coarser dust which is richer in Silica (SiO2). This is the case of several types of biomasses, such as Forestry Residues, Palm Shell, Empty Fruit Bunch, Rice Husk and many types of coal. Indeed, the Median Volume Diameter (MVD) of the fly ash coming directly from the furnace is typically above 11µm

The particles escaping the pre-separator are much finer and have a MVD of ~8µm. This forces the use of a high efficiency final dedusting system. These have different drawbacks, as follows:

Regular Cyclones and Multicyclones | Problem: Low Efficiency

Preferred technology for particle collection in industrial boilers and furnaces due to its robust construction, absence of moving parts and general application (low CAPEX).

Main drawback: low efficiency for small particles (<10μm) leading to non-compliance with new emission limits.

Bag & Ceramic Filters | Problem: O&M costs

Bag filters are very efficient (> 99.9 %) but can be very maintenance demanding in the presence of high temperatures due to frequent cleaning and changing of filter elements, which are frequently attacked by glowing particles. The ceramic filter solution is more expensive and costly to operate. In drying applications, filter clogging is a frequent problem due to high moisture.

ESPs | Problem: High Investment

Robust equipment with low pressure drop and very effective for a given range of dust required. However, efficiency may drop outside that range as a consequence of temperature changes. Require to be operated by trained and specialized personnel. Ultimately, ESPs high investment costs are out of reach of many companies.

Wet Venturi Scubbers and WESPs | Problem: Secondary Pollution

Scrubbers can be very efficient by increasing pressure drop and energy costs. WESPs work with low pressure drops but have high OPEX and CAPEX. Both require the use of water, originating secondary pollution.

Clients` needs include a highly efficient final dedusting system at a reasonable price, robust enough to operate for several years without significant maintenance or operating costs and avoiding production downtime.

ACS solutions include low pressure drop, compact and long-lasting pre-separators and high efficiency cyclones which are a real alternative to other more maintenance demanding or costly dedusters to reach emissions as low as 30mg/Nm3. Please see our case studies for several specific industrial segments.