- Home

- Companies

- Eldan Recycling A/S

- Products

Eldan Recycling A/S products

Eldan - Downsizing Cables and Sorting Metal for Wire Recycling Plant

Recycling cables has been a profitable business for decades, since copper and aluminium harnessed from old cables can be recycled again and again. Cable recycling is the process of downsizing cables and sorting metal from insulation for the purpose of recycling. The most sought-after resources are copper and aluminium.

Pre-Choppers / Shredders

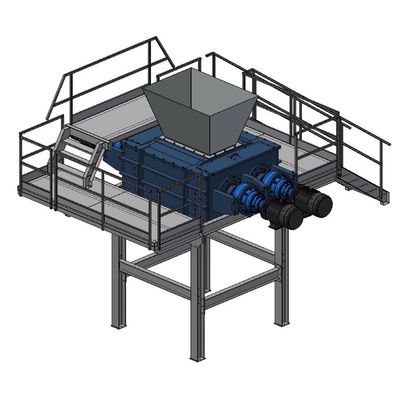

ELDAN - Model MC1348/90 & MC1348/160 - Multi Chopper

The Multi Chopper has a low speed, high torque rotor enabling processing of tough materials. It is powered directly by Hägglund hydraulic motor and power unit enabling automatic reverse for overload protection thus minimizing knife damages. Knives available in different steel qualities providing the optimum solution for processing of your specific material. Easily exchangeable wear parts give you a virtually indestructible machine which is easy to maintain. Screens with different hole sizes available to make your production flexible.

ELDAN - Model S1000 / S1500 - Ring Shredder

Impact rings ensures opening of material and liberation of metals. The impact rings are mounted on 4 secondary shafts located on the rotor. Easily exchangeable grates available with different hole sizes. Exchangeable wear parts give you a virtually indestructible machine.

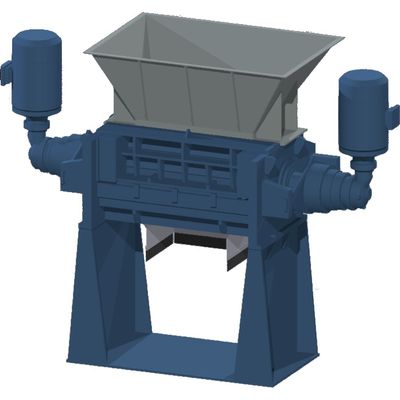

ELDAN - Model SC1412/160, SC2109/250 & SC2118/250 - Super Chopper

The ELDAN Super Choppers are heavy duty pre-choppers designed as first step in any recycling process. The Super Choppers can be used for pre-chopping of most materials like tyres (without prior debeading), all types of aluminium scrap, cables, electronic and electrical waste (i.e. WEEE), refrigerators, municipal solid waste (i.e. MSW), wind mill wings (cut-off), plastics and industrial waste.

ELDAN - Model TS970-II / TS1460-II - Twin Shaft Pre-Shredder

The simple construction makes the change of the hooked knifes easy, by lifting up the entire rotor. Two rotors are each equipped with electrical motors and high torque gearboxes. Provided with 2 rotors and wear resistant hooked knives for efficient pre‐shredding. The hooked knifes are available in different thicknesses for controlling the size of the output. Two frequency converters ensures a very flexible operation i.e. individual setting of RPM, overload protection, auto reverse at overload and high torque from zero RPM. Stand and inlet hopper is customized for the individual set up.

ELDAN - Model TSCC 1200 FD180 50x50/TSCC 1200 FD180 100x100 - Twin Shaft Clean-Cut Shredder

The ELDAN Twin Shaft Clean-Cut Shredder is the perfect solution for one step production of clean-cut chips from car and truck tyres. The simple construction enables easy knife change, by lifting up the entire rotor. Knives can also be reground. Two rotors, each equipped with two electrical motors and high torque gearboxes. Wear resistant knives for efficient pre‐shredding. Two frequency converters ensure a very flexible operation, i.e. individual setting of RPM, overload protection, auto reverse at overload and high torque from zero RPM. Up to 50% power saving. Stand and inlet hopper customized for individual set up.

Super Chopper

Eldan - Model SC1412 FD75 / SC1412 FD150 - Super Chopper-FD (Frequency Drive) - Up to 12000 kg/h

The ELDAN Super Choppers are heavy duty pre-choppers designed as first step in any recycling process. The Super Choppers can be used for pre-chopping of most materials like tyres (without prior debeading), all types of aluminium scrap, cables, electronic and electrical waste (i.e. WEEE), refrigerators, municipal solid waste (i.e. MSW), wind turbine wings (cut-off), plastics and industrial waste.

ELDAN - Model SC2109 / SC2118 - Super Chopper - Frequency Drive Up to 30000 kg/h

The ELDAN Super Choppers are heavy duty pre-choppers designed as first step in any recycling process. The Super Choppers can be used for pre-chopping of most materials like tyres (without prior debeading), all types of aluminium scrap, cables, electronic and electrical waste (i.e. WEEE), refrigerators, municipal solid waste (i.e. MSW), wind turbine wings (cut-off), plastics and industrial waste.

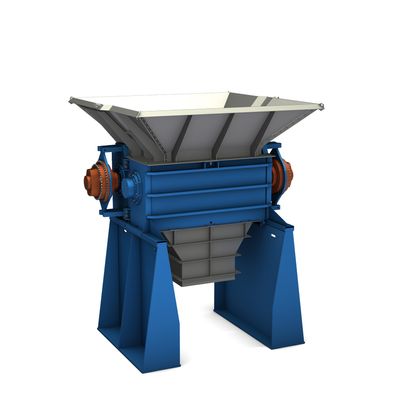

Eldan - Model SC1412-II / SC2118-II - Super Chopper II (Twin Rotor) - Up to 40000 kg/h

The Eldan Super Choppers are heavy duty pre-choppers designed as first step in any recycling process. The twin rotor version of the Super Chopper is a further development which enable you to process voluminous and tough material. Proven technology at its best.

Raspers

ELDAN - Model MPR80 / MPR120 / MPR160 / MPR200 - Multi Purpose Rasper Up to 10.000 kg/h

The high inertia from the flywheel gives a more even load of the machine, and therefore a higher cutting power. The machine is belt driven for simple transmission. The rotor is manufactured and designed for minimum wear. The machine is designed for quick and easy change of knives and screens. Screens with different hole sizes available for flexible production. Exchangeable wear parts give you a virtually indestructible machine.