Freylit Umwelttechnik GmbH products

CPI - Oil Separators for Industries

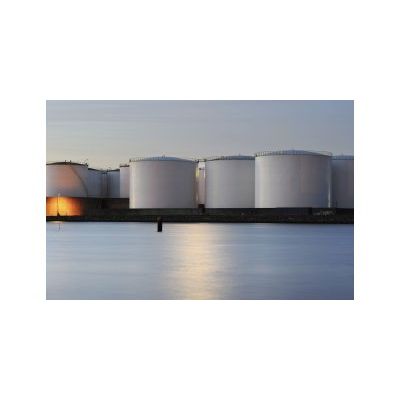

FREYLIT - Oil Terminals

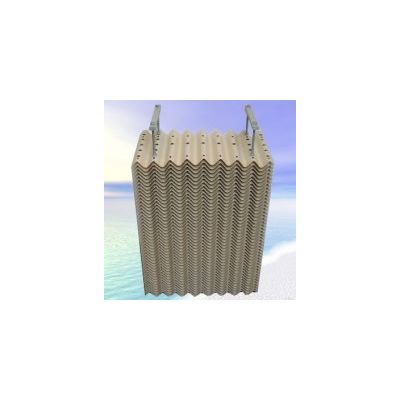

SPECIAL FEATURES of our CPI - INDUSTRIAL OIL SEPARATORS are: Separator footprint is significantly smaller than TPI (inclined/tilted plate separators) or API separators, thus reducing civil construction cost, while achieving the same or better oil outlet concentration. CORRUGATED HORIZONTAL COALESCENT PLATES (material Polypropylene) - LIFETIME OF MINIMUM 20 YEARS.For high temperature applications FREYLIT also manufactures coalescent plates from POM (Polyoxymethylenhomopolymer). The DISTANCE BETWEEN OUR PLATES can be switched between 6 mm and 12 mm by turning the same plates 180°, to increase the efficiency of the separation process. OIL OUTLET CONCENTRATION below 5 ppm (5 mg/Liters) The separated oil droplet size is calculated by our FREYLIT proprietary computer design program. More than 30 years experience with all kind of applications, dimensions, designs and deliveries of OIL WATER SEPARATORS.

FREYLIT - Oil & Gas Fields

SPECIAL FEATURES of our CPI - INDUSTRIAL OIL SEPARATORS are: Separator footprint is significantly smaller than TPI (inclined/tilted plate separators) or API separators, thus reducing civil construction cost, while achieving the same or better oil outlet concentration. CORRUGATED HORIZONTAL COALESCENT PLATES (material Polypropylene) - LIFETIME OF MINIMUM 20 YEARS, For high temperature applications FREYLIT also manufactures coalescent plates from POM (Polyoxymethylenhomopolymer), The DISTANCE BETWEEN OUR PLATES can be switched between 6 mm and 12 mm by turning the same plates 180°, to increase the efficiency of the separation process. OIL OUTLET CONCENTRATION below 5 ppm (5 mg/Liters), The separated oil droplet size is calculated by our FREYLIT proprietary computer design program. More than 30 years experience with all kind of applications, dimensions, designs and deliveries of OIL WATER SEPARATORS.

Wash Water Recycling Systems

FREYLIT - Model CHV 600 - Wash Water Recycling System

With the CHV system we remove suspended solids by a three stage process. By stainless steel pump protector coarse screen to block out solid waste.By hydro-cyclone to remove larger particles. By dissolved air flotation to remove fine flakes and particles.Freylit has been engaged for many years in researching new wash water recycling technology. Recently we discovered that, when wash chemicals are mixed together with dirt and exposed to sunlight algae will grow. These algae will stick to pipes, tanks, car wash and other surfaces and act as a culture for bacteria. These bacteria will cause bad odour. To combat this problem Freylit developed the high voltage electrode which does not only kill bacteria, but is also very effective in preventing the growth of algae. Moreover, the High Voltage Electrode will cause a flocculation of fine particles.

FREYLIT - Model CHV 200 - Wash Water Recycling System

Freylit has been engaged for many years in researching new wash water recycling technology. Recently we discovered that, when wash chemicals are mixed together with dirt and exposed to sunlight algae will grow. These algae will stick to pipes, tanks, car wash and other surfaces and act as a culture for bacteria. These bacteria will cause bad odour. To combat this problem Freylit developed the high voltage electrode which does not only kill bacteria, but is also very effective in preventing the growth of algae. Moreover, the High Voltage Electrode will cause a flocculation of fine particles.

FREYLIT - Model CHVTP 600 - Wash Water Recycling System

With the CHVTP system we remove suspended solids by a three stage process. By stainless steel pump protector coarse screen to block out solid waste.By hydro-cyclone to remove larger particles.By dissolved air flotation to remove fine flakes and particles.Freylit has been engaged for many years in researching new wash water recycling technology. Recently we discovered that, when wash chemicals are mixed together with dirt and exposed to sunlight algae will grow. These algae will stick to pipes, tanks, car wash and other surfaces and act as a culture for bacteria. These bacteria will cause bad odour. To combat this problem Freylit developed the high voltage electrode which does not only kill bacteria, but is also very effective in preventing the growth of algae. Moreover, the High Voltage Electrode will cause a flocculation of fine particles.

EKOLIT - Model X Series - Recycling System

The new EKO-LIT series, which we launched in 2002, is the most economical and efficient recycling system we have ever developed. It brought several significant advantages which we would like to briefly point out : With the EKOLIT system we remove suspended solids by a two stage process. a) By hydro-cyclone to remove larger particles. b) By fine filter, which are equipped with an automatic back-flush system (20 or 50 micron). The back flush is activated after every car wash cycle is completed. Moreover, the filter mesh is made of stainless steel and does not need periodic changing. By high voltage electrode (30,000 Volts / 300 mAmps.). By our well established water stabilizer. Freylit has been engaged for many years in researching new wash water recycling technology. Recently we discovered that, when wash chemicals are mixed together with dirt and exposed to sunlight algae will grow.

Model EKOLIT Series - Recycling System

All Recycling Systems have the same purpose: Remove solids from the wash water (to avoid damage to car surface and clogging up of valves and nozzles of the car wash) and kill bacteria (to avoid bad smell and illness or customers and workers from bacteria). The EKOLIT system is in both functions the most efficient and economical worldwide.

Mobile Oil Separators

FREYLIT - Mobile Oil Separators for Oil Spill on Seas / Oceans

FREYLIT Oil separators are designed to the exact specification and requirements of our client.The modular plate-pack system is the perfect solution for oil/water separation.FREYLIT coalescent plate separators are the most economic method of treating process water efficiently. FREYLIT has been producing and installing a wide range of oil/water separators

FREYLIT - Mobile Oil Separators for Oil Spill on Lakes / Rivers

The FREYLIT modular plate-pack system the perfect solution for oil separation in large scale industrial oil sperarators. In many industries process waters are contaminated with oil which needs to be removed before returning the water into the process cycle for example in steel mills. Coalescent plate pack seperators are the most economic method of treating such process wateres efficiently. Large scale oil separators are also used for the environmentally friendly disposed of waste waters from power stations, fuel storage facilities, airport, harbours, marine oil terminals, etc. FREYLIT oil separators are also used for the recovery of valuable oil from oil water mixtures at oil fields.

Oil-Spill Prevention & Clean Up Systems

Freylit Ocean Guard - Floating CPI Oil-Water-Separator for Prevention and Clean Up Oil-Spills

The floating oil separator is a compact, low-maintenance system for preventing oil from spreading on water surfaces in the event of oil accidents.