- Home

- Companies

- Green Machine LLC

- Products

Green Machine LLC products

Recycling Systems

Municipal Solid Waste Recycling (MSW) Systems

Mixed Waste processing facilities in recent years have developed a bad reputation. Many in the industry refer to these plants as Dirty MRF’s! Additionally many technically advanced processing facilities have quickly gone out of business. Don’t let either of these facts scare you away from looking into a Green Machine municipal solid recycling system. Other manufacturers failed due to their extreme levels of technological complexity and high labor interface.

Optical Sorting System

Today’s Commodity Markets often require the deployment of automated artificially intelligent mechanical sorting systems to meet both market purity and system throughput standards. No longer can the human eye be trusted exclusively to identify commodity grades and impurities nor can manual labor physically of financially meet current industry demands.

Recycling Equipment

Green Eye - Optical Sorting Recycling System

Green Eye Product Test Facility is prepared to solve your recycling challenges at our Hampstead, NH Research and Development test facility. Imagine the advantage of operating one optical sorter with the flexibility to sort multiple commodities with the ability to evolve with each market challenge in real time. It takes a surprising amount of manpower and time to effectively sort a large amount of recyclables. While previous attempts to automate sorting haven’t been that successful, the Green Eye® Optical Sorting Recycling System uses new patented technology to make the process quick, easy, and error-free.

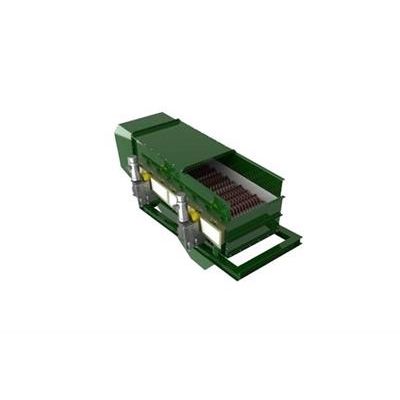

Green Screens - Model OCC - Separation Recycling Equipment

GREEN SCREENS® are the industry’s leader in screening technology. Our OCC Disc Screens throughput is the highest in the industry, our cleanliness is best and our wrap resistant shafts saves loads on maintenance. Our most important feature is that our disc spacing is adjustable so you determine the sorting outcomes you need. Both our discs and our spacers are removable and adjustable without removal of the shafts. Every individual screen zone has a minimum of two drives because “Horsepower Matters”. Each shaft operates progressively faster while overall disc speed is quickest in the industry. Alternating finger disc designs are deployed to enhance agitation when needed. Throughputs of between 18 – 60 TPH are attainable through our screen systems.

Green Screens - Mini/Mid Polisher Separation Recycling Equipment

GREEN SCREENS®mini/mid polisher separation screens offer most of the same attributes as our famous full size screens. Differences are that these screens process fewer tons per hour, cost less and can be located within an 18’ building clear height. GREEN MACHINE® systems utilize these smaller polishers for final removal of flattened containers from the fiber stream but can also be used as a primary separation screen for recyclers running 12 or less tons per hour. Like the full size screening systems, our patented GREEN SCREENS® wrap resistant spacer systems and field adjustable disc spacing, coupled with the industry’s lowest per ton rubber disc wear cost, makes GREEN SCREENS® the recycling industry’s best performing separation system.

Green Screens - Polisher Separation Recycling Equipment

GREEN SCREENS® polisher separation screens are primarily designed to separate two dimensional items like fiber from multi dimensional items such as containers. Separate Fibers From Containers using our large polisher screen. Our screen uses rapidly rotating discs mounted on shafts with each shaft moving progressively faster than the last. This combined with separately hinged upper and lower decks that are fully articulable gives you control over discharge contamination of both fiber and container streams.

Green Machine - Eddy Current Separators

The Green Machine® eddy current separators are designed to automatically separate and sort non-ferrous metals such as aluminum cans from a mixed materials waste stream. The separators work by utilizing a system of rare earth magnets. These magnets rotate at a high rate of speed to create what is called an “Eddy Field”. This field pushes non-ferrous metals away from the other items in the waste stream, making it very easy to separate them out.

Green Machine - Metering Bin Drum Feeder System

The Green Machine®metering bin drum feeder system can be added to most recycling applications and systems to increase their system efficiency. Since it was first implemented, the Green Machine® metering bin feeder system has been recognized as the most durable and efficient system in the industry. In most cases, customers will see a throughput increase of 30 percent once the system has been implemented at the feed end of the sorting lines. The feeder system has been designed to allow for the homogeneous metered flow of materials. This eliminates the need for black belt conditions and enhances presort and screen performance in bulk handling waste recycling equipment systems. The overall bin capacity of our metering bin feeder system ranges from 40 to 120 cubic yards. This often means that one loader is able to handle the duties of the entire plant.

Green Screens - Glass Breaker/Fines Removal System

GREEN SCREENS® Glass Breaker/Fines Removal System are available in a variety of sizes. Remove Glass and Fines (2” Minus) from highly contaminated recyclables to get a cleaner end-product and improve downstream equipment processing. Our Glass Breaker Screen/Fines Removal Screening Systems are capable of processing Mixed MSW and C&D Waste Streams.

Green Eye - Hyperspectral Robotic Sorting System

Green Machine’s newly developed Green Eye® Robotic Sorter are the most advanced robotic systems on the market. Our robotic sorters meet specs that no other robotic sorter can match. We’re the first company to make it possible to put up to 30 robots in a row, all functioning off a single Green Eye® Hyperspectral Vision System. Each robotic arm can perform a minimum of 100 picks/minute and can be trained to pick four separate commodities at the same time. Our robotic arms can be built side-by-side to cover conveyor belts up to 72” wide.