k-Space Associates, Inc. products

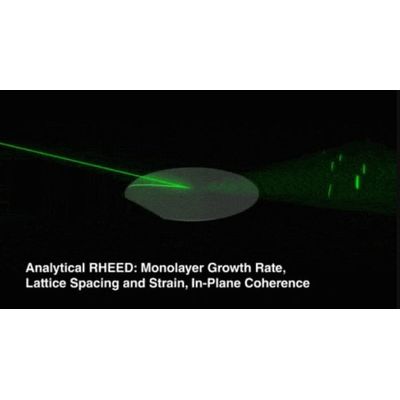

Model kSA 400 - Analytical Reflection High-Energy Electron Diffraction (Rheed) System

The kSA 400 analytical Reflection High-Energy Electron Diffraction (RHEED) system puts the power of RHEED at your fingertips. Whether analyzing a static diffraction pattern or acquiring data at multiple azimuths during substrate rotation, the kSA 400 makes quantitative RHEED analysis easy. Exploit the power of RHEED with the kSA 400!

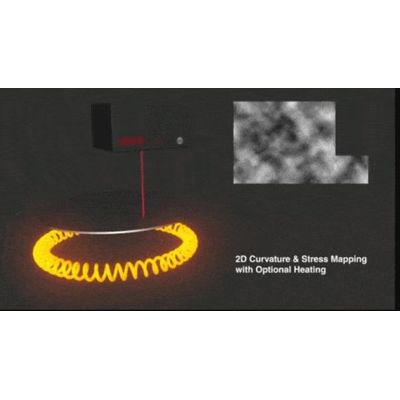

Model MOS UltraScan/ThermalScan - Full-Sample Mapping of Curvature, Stress, Tilt, and Bow Height

The kSA MOS UltraScan and kSA MOS ThermalScan systems are ex situ, flexible, high-resolution scanning wafer curvature, bow, and tilt-measurement systems. The kSA MOS UltraScan and kSA MOS ThermalScan systems are flexible, high-resolution scanning wafer curvature, bow, and tilt-measurement systems. Based on proven and patented kSA MOS technology, the kSA MOS UltraScan uses a laser array to map the two-dimensional curvature, wafer bow, and stress of semiconductor wafers, optical mirrors, glass, lenses – practically any polished surface. For room temperature measurements, explore the kSA MOS UltraScan. If you want to know how your wafer changes with temperature, explore the kSA MOS ThermalScan.

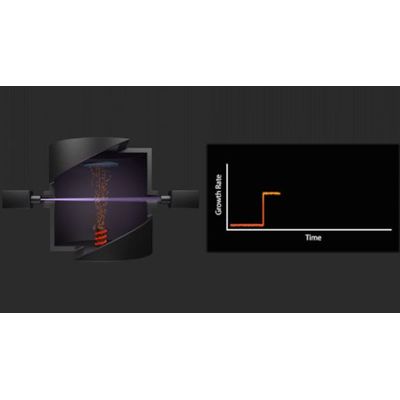

Model ACE - Atomic Flux Control

kSA ACE provides atomic flux control with accurate and high-resolution source flux and growth rate monitoring for thin-film deposition. The kSA Atomic Control for Epitaxy (ACE) metrology tool is a highly sensitive instrument that measures the in situ flux rate of atomic species using the principle of atomic absorption spectroscopy. The kSA ACE system uses conventional hollow cathode lamps (HCLs) to generate the atomic emission for the elements of interest. It also utilizes a high-sensitivity, UV-optimized solid-state spectrometer to monitor the absorption, along with a second spectrometer to monitor signal drift from the HCLs. Because the technique is inherently material specific, the signal does not respond to other species or radiation in the chamber. kSA ACE can measure each material of interest independently with high accuracy, providing precise material-specific flux control in multi-source deposition processes.

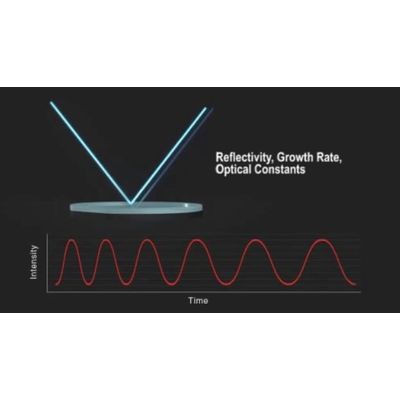

Model RateRat Pro - Real-Time Deposition Rate Monitoring and Process Control

kSA RateRat Pro is a compact, convenient and easy-to-use optical metrology tool for thin-film characterization. Its unique capability is to measure, in situ and in real-time, optical constants (n and k), deposition rate and film thickness. kSA RateRat is a compact and easy-to-use optical metrology tool for real-time thin-film process control and measurement of semitransparent films. It uses a proprietary algorithm which continuously updates the optical constants of the film derived from a least-squares fit to the optical reflectivity curve. kSA RateRat determines deposition rate, layer thickness, and optical constants (n and k) with as little as 600 Å of material deposited. kSA RateRat has many options to suit the needs of different applications and materials, including different laser/LED wavelengths (405, 532, 658, 950, and 1050 nm), as well as software integration capabilities.