- Home

- Companies

- Parkson Corporation

- Products

Parkson Corporation products

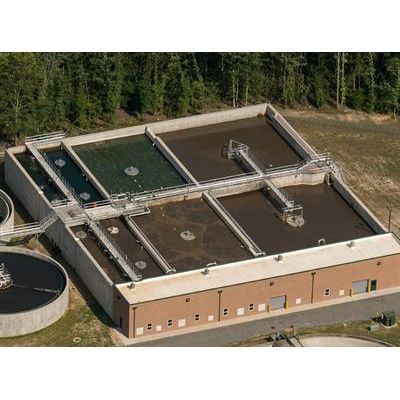

EquaReact - Combined Equalization and Treatment System

EquaReact® is a unique Wastewater Treatment process that combines hydraulic flow equalization and multi-stage (anaerobic, anoxic, or aerobic) Activated Sludge treatement as a system offering to provide Biological or Enhanced Nutrient Removal in both Industrial and Municipal markets. The EquaReact® System reduces land requirements, energy consumption, and capital costs while increasing the overall treatment system performance and efficiency.Headworks Continuous in-Channel Screens

Aqua Guard - Continuous Self Cleaning Moving Media Screen

The Aqua Guard is a rugged and proven self-cleaning in-channel screen that uses a unique filter element system designed to automatically remove a wide range of floating and suspended solids from a wastewater stream. These unique elements are woven together on stainless steel shafts to form the endless moving belt that collects, conveys and ultimately discharges the solids that are being removed from the treated wastewater. The Aqua Guard is capable of performing in a wide range of applications and element spacing settings – from 1mm to 30mm –depending on the requirements of the specific treatment process.

Aqua Guard - Model PF - Perforated Plate Media Channel Screen

The Aqua Guard PF screen is a self-cleaning, in-channel screening device that utilizes perforated plate media to automatically remove a wide range of solids from wastewater. The screen design is built on the Aqua Guard® bar/filter screen chassis that has been proven successful with over a thousand units installed and in operation. The Aqua Guard PF can be made with the heavy-duty “S” chain or the standard duty chain.

Aqua Guard UltraClean - Self Cleaning Moving Media Channel Screen

The new Aqua Guard UltraClean screen outperformed the standard Aqua Guard screen in side-by-side capture rate tests by over 50%. The new upper UltraClean “head” design makes the Aqua Guard UltraClean superior and it is available for new units or can be rebuilt on existing ones. The Aqua Guard® UltraClean™ screen, a self-cleaning in-channel screening device, utilizes a unique filter element system designed to automatically remove solids larger than element spacing. Aqua Guard® screen filter elements form an underwater grid that ensures better capture rates when compared to rake bar screens that utilize only vertical bars for screening. A specific configuration of filter elements is mounted on a series of parallel shafts to form an endless moving belt that collects, conveys and discharges solids for further processing or disposal.

Screenings & Headworks - Dewatering

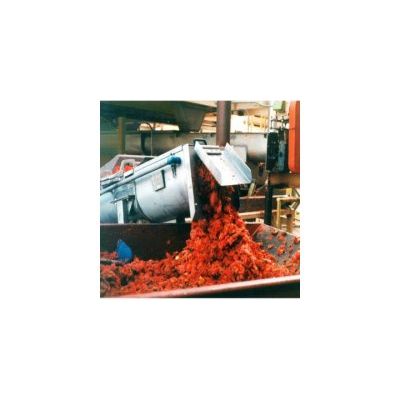

Aqua WashPress - Dewatering Screw Press

The Aqua WashPress can economically and effectively wash and dewater screenings from in channel and rotating screens in a variety of applications. The Aqua WashPress will lower hauling and disposal costs by reducing weight and volume of screenings. Organics and biosolids are commonly caught along with the appropriately screened solids. If not removed, these items retain water, inhibit drainage, emit odors and result in excessive disposal costs.

Helixpress - Shaftless Spiral Dewatering Press

The Helixpress unit is the cost-effective solution for dewatering the screenings collected by any type of screen. It is an all-in-one conveyor, compactor and dewaterer. It utilizes a combination of drainage, compaction and dewatering to reduce weight and volume and ultimately decrease hauling and disposal costs. The Helixpress is designed to pass the EPA Paint Filter Test which is required on solids dryness for landfill applications. It can convey solids as far as 30 ft. and at a maximum of a twenty degree angle. It is designed to handle screenings up to 157 cu.ft./hr. Multiple screens may discharge to a single Helixpress® unit.

Hypress - Hydraulic Ram-Style Dewatering Press

The Hypress Dewatering Press is a reliable performer that dewaters and compresses coarse and fine screenings up to 35% dry weight, depending on the material. It reduces volume as much as 75% to minimize hauling and landfill costs. The Hypress unit is rugged, durable and fabricated of corrosion-resistant 304L stainless. It comes with a drain pan that collects water pressed from the screenings.

Screenings & Headworks - All-in-One Units

Parkson Combi - Packaged Headworks Systems for Sewage and Septage Receiving

The Combi is an all-in-one headworks solution that integrates fine screening, screenings dewatering and grit handling in a single, pre-fabricated, stainless steel unit. The system is designed for sewage or septage pretreatment at the wastewater treatment plant. All components are engineered for proper interface, low maintenance, optimal throughput and simple, reliable operation. A variety of options are available to meet site specific requirements. Fine screens are available in opening sizes of 1/8” (3mm) or 1/4” (6mm) diameter to meet your needs.

Helisieve - Screening, Conveying and Dewatering System

The Parkson Helisieve In-Channel Fine Screen combines fine screening, conveying and dewatering to create a highly economical system that produces screenings dry enough to take to a landfill without the need of an additional dewatering press. Screen openings are available in the standard ¼” perforations or optional 1/8”. The heart of the system is a shaftless spiral with a brush in the screen basket area to keep the screen clean. Operation of the spiral is based on level control upstream of the screen basket. Screened solids are conveyed out of the channel, dewatered and discharged into a dumpster or conveyor.Units are available in a tank when a channel is not available. A common in-tank option to pre-treat septage (with special controls) prior to being accepted in a wastewater treatment plant.

Screenings & Headworks - Conveyance

Helicon - Shaftless Spiral Conveyor

The Helicon spiral conveyor is the answer for efficient, reliable automatic transport. The conveyor is frequently used in conjunction with other Hycor equipment to create a solids management system that conveys the screened solids to washing or dewatering, and ultimately to disposal. The Helicon conveyor is totally enclosed. Bolt-on covers contain odors, keep extraneous materials out, eliminate spills and minimize housekeeping. The Helicon’s shaftless spiral design is extremely simple, uncomplicated and will provide years of trouble-free performance. The shaftless spiral provides clear, unrestricted throughput with no center shaft to snag or wrap solids. There are no intermediate hanger bearings to obstruct flow and no maintenance-intensive end bearings.