RIFOX - Hans Richter GmbH Spezialarmaturen products

RIFOdry

RIFOdry - Dryer/Separator

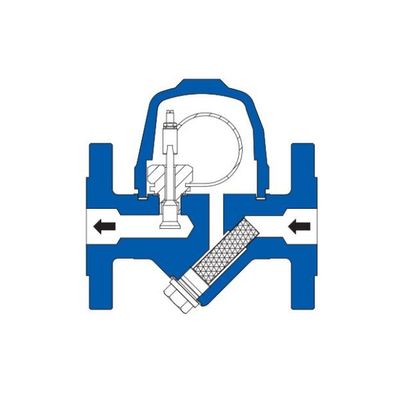

A control device makes the medium loaded with liquid swirled and rotating with high peripheral speed in the separating chamber thus producing centrifugal forces which eject the specifically heavier particles like condensate, dirt etc. The separated particles glide on the tank wall over to the collecting chamber. The purified gas goes from the separator over to a central submerged pipe fitted with a blade ring with detaching edge preventing the liquid from running into the submerged pipe. The collecting room is shielded such as to prevent the separated liquid from being whirled up and entrained. The collecting room can be automatically evacuated by a Rifomat float trap.

RIFOdry - Automatic Fine Dryer

With moist loaded gas flow becomes by a control device a spin gives. This develop centrifugal force, which discharge specific heavy particle such as drops and condensation droplets. The drops slide along the housing wall downward into the collecting area. The drops of moisture leaves the separator trom the bottom upwards over the so-called Immersion tube. A screen of the collecting area prevents raising and thrilling of discharged liquid. The collecting area Is emptied by a trap.

RIFOair

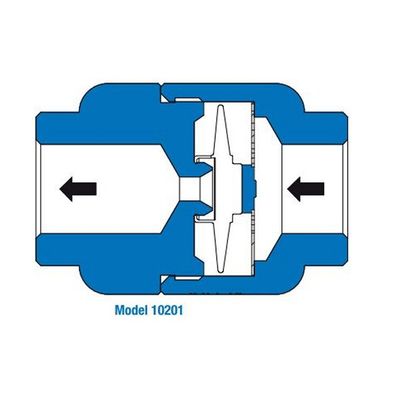

RIFOair - Venting Valve / Vacuum Breaker

As soon as the Internal vessel pressure drops below atmospheric pressure conditions the valve ball rises from the seat and ambient air flows Into the section to be protected. Rises the Internal vessel pressure above the ambient pressure the valve automatically closes. Vacuum breakers do not provide protection against overpressure.

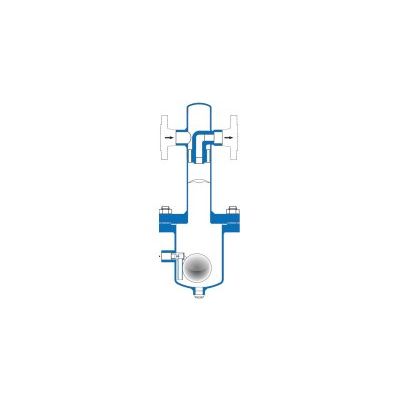

RIFOair - Automatic Vent Valve with Control Unit C

Application: Venting of liquid carrying systems. Function: The float control assembly discharges air and gases from all liquid carrying systems without time lag, independent of pressure and temperature variations. With the float in the lower position the outlet cross-section is open. Air and gases escape through the opened cross-section. Rising of the liquid level lifts the float and causes to close the outlet. Special characteristics: High tightness by soft-sealing control, for particularly application in sea water.

RIFOair - Thermo-Controlled Bi-metallic Vent Valve

Application: For venting ot steam chambers. Function: Automatic venting during start-up. A temperature drop opens while an Increase of temperature closes the passage. As steam temperature the valve closes. Special characteristics: The 34-corroslon resistant bl-metal control element forms a single Item. Due to the large tolerance between valve stem and valve housing, the unit Is Insensitive to contamination. Valve travel can be asjusted to suit special system requirements, such as supersaturatlon and backpressure. Installation: Horizontal or vertical.

RIFOair - Thermo - Controlled Capsule Vent Valve

Application: Venting of liquid carrying systems. Function: Automatic venting for start up and on duration. Decreasing temperature opens the outlet wtiile increasing temperature closes it. The valve closes at steam temperature. Special characteristics: reaction without time delay, good for venting of pre-lnstalled heating surfaces, valve unit complete made of stainless steel, lost of steam would he prevented. Installation: horizontal or vertical

RIFOlevel

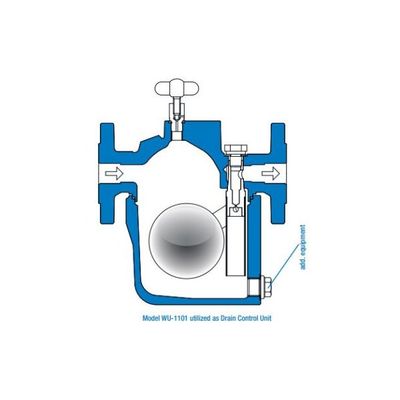

RIFOlevel - Drain Control Unit

Housing material: EN-GJS-400-18-LT (5.3103). Connections: DN 15,20,25,40,50 flanges, connecting dimensions. according to DIN EN 1092-2. Flange connecting dimensions for1/2n-2" Class 150 and Wl, 3/4". Class 300 ace. to ANSI. Nominal pressure stage: PN 25.

RIFObi/ka

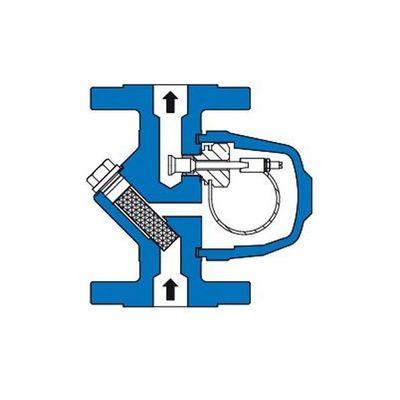

RIFObi - Thermo Bimetallic Condensate Trap

Housing Material: P250GH Nominal Diameter: DN15, DN20, DN25, DN40, DN50 Connections: Flanges DN15, DN20, DN25, DN40, DN50, according DIN EN 1092-1. Flanges V. 1`v. 2", according ANSI B 16.5. Class 150/300. Female thread G1/2", GVa", G1" (BSP) according DIN ISO 228-1. Female thread Vz", %", 1" NPT according ANSI B1.20.1. Butt weld DN15, 20,25, according DIN EN 12627 and ANSI B 16.25. Socket weld DN15 (1/2"), DN20 (3/4"), DN25 (1"), DN40 (1 1/2"), DN50 (2") according DIN EN 12760 and ANSI B 16.11.

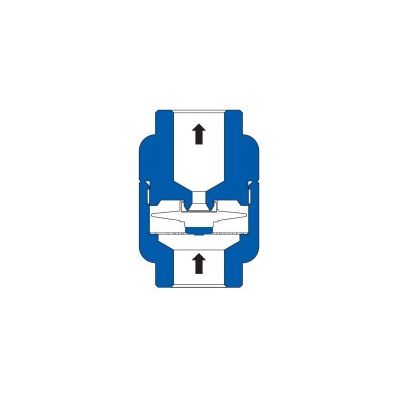

RIFOka - Thermo Controlled Capsule Trap

Housing Material: 1.4104. Nominal diameter: DN15, DN20, DN25. Connections: • Female thread G W-1" (BSP) ace. DIN ISO 228-1 • BSPT, NPT thread or other connections on request. Nominal pressure stage: PN 40. Working media: Steam and condensate. Not applicable for media of fluid group 1..