- Home

- Companies

- Scheuch GmbH

- Products

Scheuch GmbH products

Modular Bag Filter Products

Scheuch Scaloncomp - Modular Bag Filter System

As individual as your requirements: The Scheuch compact filter can be used in almost all industries for dust extraction and provides the highest level of modularity. With variable layouts and construction heights, we enable flexible planning possibilities adapted to the local conditions. Thanks to the compact design, the Scheuch compact filter is ideal for narrow space thanks to its limited base area and installation height, and has been specially designed for low flow rates. Designs as bin vent filters and filters with a hopper or trough including an integrated dust discharge screw are available.

Scheuch Scalonround - Compact Round Bag Filter

As individual as your requirements: the Scheuch round filter is a compact, heavy-duty filtering separator that is suitable for almost all industrial dedusting applications and pneumatic conveying systems. Variable floor plans and installation heights create flexible planning options that can be optimally adapted to local conditions. With a flow rate of up to 150.000 Am3/n, the round filter covers a wide range of performance. The round design allows for flexible and space-saving planning and is particularly suitable for confined spaces. Different designs, such as top filters and filters with a dust collection hopper and integrated pre-separator, ensure flexible operating conditions. The integrated pre-separator, which acts as a centrifugal separator, is particularly effective at separating large quantities of material, making it an ideal solution for conveyor systems and central vacuum cleaning systems.

Wood Based Panel Industry- Dryer Exhaust Gas Cleaning

Model SABA - Biological Exhaust Gas Cleaning Scrubbers

The principle of biological exhaust gas cleaning is based on microorganisms converting the contents of exhaust gas into harmless products. As the process always has to take place in a more aqueous phase than is available in the microorganisms` habitat, the microorganisms are either grown in a film of moisture on a substrate or suspended in an aqueous solution. The microorganisms are aerobic bacteria that oxidise the contents when oxygen is present.

Model SENA - Wet Electrostatic Separation System

Model SAWA - Wet Scrubbers

The basic principle of wet scrubbers for pre-treatment or final treatment of exhaust gases containing contaminants. In the quenching area, an intensive water injection process binds the dust particles in the gas stream with water. At the same time, the raw gas is cooled until the saturation point is reached. In the mist collector, the dust-laden, agglomerated drops of water are removed from the gas stream by a centrifugal separator. The wet scrubber is operated in a closed water circuit for water treatment purposes. The solids captured in the water are separated from the circulating water by a reliable screening unit.

Wood Processing Industry - Extraction – Dedusting – Conveying

Implus - Extraction Bag Filter

The IMPULS filter- a bag filter in cyclofilter-design (also designated as roundfilter or cyclone filter) - is a compact, heavy-duty separator. Because the crude gas inflow area is implemented as a centrifugal separator (cyclone principle), it is able to separate very large amounts of material. That is why cyclofilters are particularly well suited for use in pneumatic conveyor systems or dust extraction plants like pneumatic high-pressure (HP) conveying systems or in vacuum cleaning systems. For machine extraction and dedusting purposes, we offer a complete range of products and services for everything involved in chipboard, MDF and OSB manufacturing – from chip and fibre processing, to production itself, all the way through to finishing.

Pneumatic Conveying Systems

Pneumatic systems are extremely safe and reliable and – because they contain hardly any mechanical moving parts – are virtually maintenance-free and non-wearing compared to mechanical conveyors.

Model SAP & ESAP - Press Fume Extraction Unit

When it comes to exhaust air cleaning following continuous pressing in the OSB chipboard and fibre board industry, Scheuch offers two systems. TheSAP performs exhaust gas pre-treatment, which then allows the exhaust gas to be fed to a final treatment area via long pipelines. The ESAP, meanwhile, acts as a final treatment system and is able to satisfy stringent requirements with its integrated wet electrostatic precipitator module. It ensures the maximum possible degrees of particulate and blue haze separation. It is used in cases where no final treatment system is available or where using connecting lines would not be financially viable.

Metals Industry- Iron/Steel Industry

Collecting Exhaust Air Plants

Industrial Minerals Industry- Cement Industry

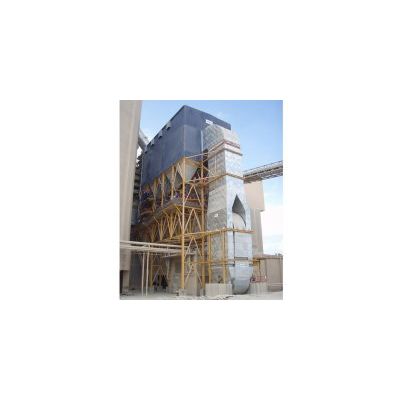

Kiln - Dedusting Filter

Thanks to the development of filter media that is suitable for higher exhaust gas temperatures and the growing trend towards the use of secondary fuels, bag filter plants have eclipsed virtually every other kind of system when it comes to today`s kiln dedusting applications, with some electrostatic precipitators being converted into bag filters.