- Home

- Companies

- Scheuch GmbH

- Products

- Kiln - Dedusting Filter

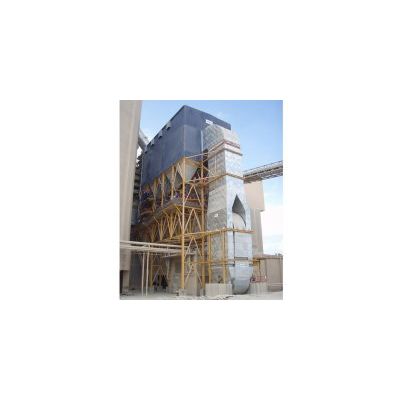

Kiln - Dedusting Filter

Thanks to the development of filter media that is suitable for higher exhaust gas temperatures and the growing trend towards the use of secondary fuels, bag filter plants have eclipsed virtually every other kind of system when it comes to today`s kiln dedusting applications, with some electrostatic precipitators being converted into bag filters.

EMC technology

Because of their size, kiln filters are the ideal application for EMC technology, allowing it to tap into their full potential for using energy efficiently and making operating cost savings. Additionally, EMC filters operate with a stable level of differential pressure – that is, without fluctuations – and are not affected by the kind of temporary overloading that occurs when secondary fuels are added, in kiln sections or during switchover processes, for instance. As a result, this application is guaranteed to offer maximum plant availability during continuous operation. This unique technology uses bag lengths of up to 10 m, something which has positive repercussions for investment costs too. Even bag lengths of 12 m and more can be used.

EMC TECHNOLOGY

Energy Minimizing Concept

EMC filter technology from Scheuch has revolutionised dedusting in the cement industry and set new standards in bag length, pressure loss, cleaning pressure and bag service life. The results point to a clear reduction in life cycle costs (LCC). Thanks to its patented status, EMC is unique and is deemed to be the Best Available Technology (BAT) for process filters - even when compared with electrostatic and reverse-air filters. More than 200 EMC filter plants installed within the first ten years of this technology outline its pre-eminent status worldwide.

Design features

- Volume flow rate up to 3,000,000 Bm3/h

- Filter area up to 40,000 m2

- Bag length as much as 12 m and beyond

- Dust quantity over 1,000 g/m3

- Hot gas design up to 280 °C