UETPCB products

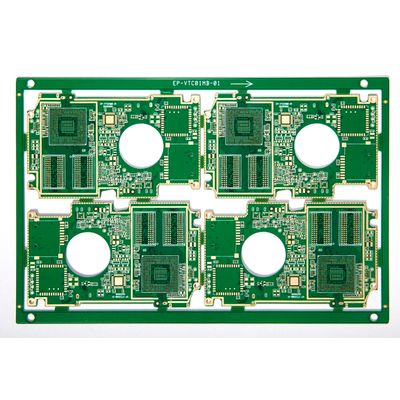

Multilayer PCBS

Multilayer PCBs are boards with more than 2 layers, including 4, 6, 8, 12… …36 layers. UETPCB’s advanced multilayer pcb manufacturing machines can accept up to 60 layers of production. Polymide, Rogers, metal cores, and many other pressing materials are available for you to choose from. You can send us your files or multilayer pcb design ideas, and we will get back to you as soon as possible with a quote.

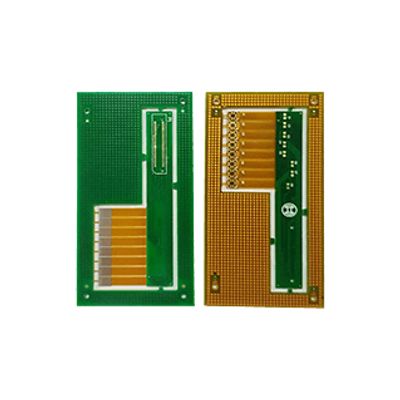

Rigid Flex PCBs

Rigid flex PCB design integrates elements from both hardboard and flexible circuit boards and features advantages of both. Therefore, the rigid flex PCB can be folded or flexed while keeping the shape of areas where need extra support. The rigid flex board is typically multi-layered and includes flexible circuit substrates joined with rigid boards. Rigid flex PCB manufacturers bury the flexible layers internally and penetrate the rigid sections of the PCB completely.

Flexible PCBs

How to select the right one from various types of PCBs for your creative projects? Is it flex PCBs? Wanted to find the answer, we need to know what is flex PCBs. Flex PCBs also known as flexible PCBs, are made of a thin insulating polymer film where will be affixed conductive circuit patterns, and typically, the PCB manufacturer coats a thin polymer over it to protect the conductor circuits. Flexible circuit boards are always designed to fit the device or product, therefore it doesn’t need comply to meet the size of the basic circuit board in component assembly. Usually, the flex PCBs are thin, lightweight, and have a well-performance in any small space and contoured shapes. There are several selections for flexible circuit boards available. You can select the single-sided, double-sided, and multilayer flex PCBs from specialized flexible PCB manufacturers and find the right PCBs is very important for your creative business.

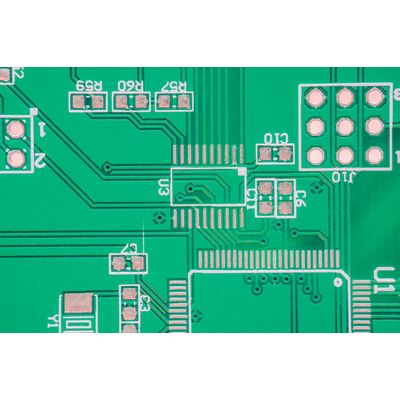

HDI PCBs

The full name of HDI PCBs is High Density Interconnector Printed Circuit Board that features a higher wiring density per unit area more than conventional printed boards. Appropriately used in high-layer count and fine laminated boards, HDI PCBs have sophisticated line and spaces, minor vias and capture pads, and higher density of connection pad density. HDI PCBs have great electrical performance and lighter weight and smaller size of the equipment. Therefore, the HDI circuit board has become the better option for costly laminated and high-layer count circuit board.