- Home

- Companies

- Guangzhou Shincci Energy Equipment Co., ...

- Products

- Shincci - Model DDC08FL - Cooled Air ...

Shincci - Model DDC08FL -Cooled Air Dryer for Low Temperature Drying System

Low Temperature Drying: Meeting the superior quality requirements in low temperature drying.(7-22°C). Integrated Design: Convenient installation. Stainless Steel: The inner partition and outer shell are made of SUS304 stainless steel to satisfy with food drying. Dry Period:Short drying cycle. Energy Saving: Compared with other dehumidification drying products can save energy more than 40%. Product Range: Meet the drying requirements of different regions and industries.

- Model: DDC08FL

- Standard dehumidification capacity (return air 12°C, 65% R.H): 10kg/h

- Refrigerant: R22

- Drying cabinet temp: 7~22°C

- Standard compressor input power: 6.0kW

- Main fan power: 0.55kW

- Condenser fan power: 1.05kW

- External cooling fan power: 1.05kW

- Total power: 8.8kW

- Power supply: 380V/50HZ

- Air cooling condenser: FL-08

- Drying control mode: Fixed value, curve program

- Control system: Touch screen + Single chip control /PLC programmable controller

- Equipment weight: 430kg

- Dimensions: 1300*888*1730mm

Cooled Air Food Dryer

Low Temperature Drying (7-22) Meet The Superior Quality Requirements

- Eel

- Abalone

- Fish

- Lobster

- Sea cucumber

- Thelenota ananas

- Crab pipa

- Sea chestnut

- Squid

- Hygiene condition good

- Closed eye drying

- Energy saving above 50%

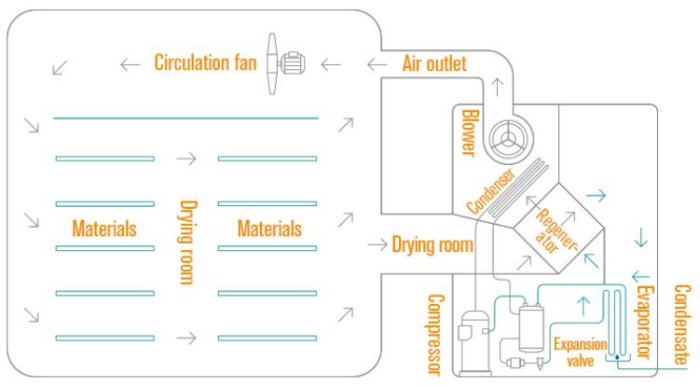

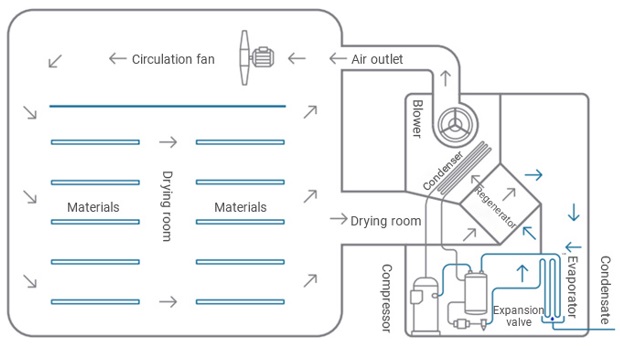

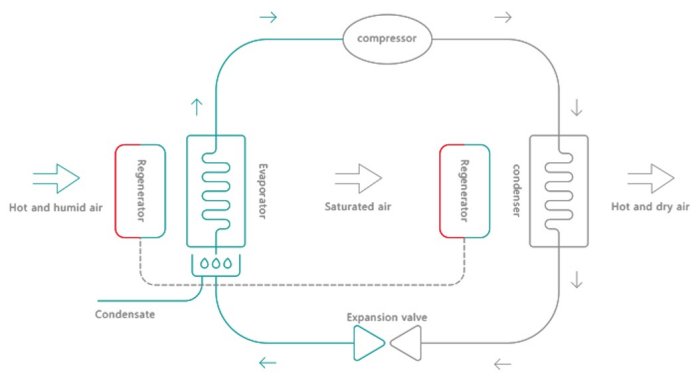

Dehumidification heat pump = combination of dehumidification (drying) + heat pump (energy recovery),which is a device that is to make humid air cool and dehumidify by refrigeration system while recovering moisture through heat pump principle to condense latent heat to heat the air. Heat source = The phase change of water vapor in the air releases condensation heat. Closed drying at low temperature (7-75?), and energy recycling during the drying process.

Air flow: heating by hot air in the drying room, the material absorbs heat and water vaporizes, the air absorbs moisture into hot and humid air → enters the evaporator, the air is cooled to below the dew point temperature, the water vapor condenses and releases the latent heat of condensation → enters the air condenser to absorb the refrigerant and release it during condensation Heat heating air → main fan → drying room.

Refrigerant process: The low-pressure refrigerant liquid is vaporized by the evaporator to absorb the air and release heat to vaporize into low-pressure superheated gas → enter the compressor → low-pressure superheated refrigerant gas passes through the compressor isentropic compression to work to high-grade, high-temperature and high-pressure gas → enters the wind condenser to release the latent heat of condensation into a high pressure liquid→expansion valve, after decompression to low temperature and low pressure liquid→evaporator.