Brooks Instrument

- Home

- Companies

- Brooks Instrument

- Products

- Brooks - Model GF40 Series - Elastomer ...

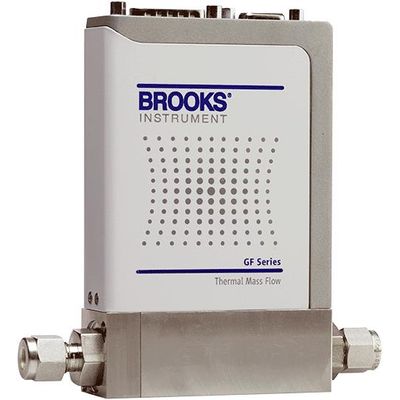

Brooks - Model GF40 Series -Elastomer Sealed Thermal Mass Flow Controllers & Meters

Multiple gases in one device equals maximum process flexibility and productivity. The GF40 Series elastomer sealed mass flow controllers and meters with Brooks Instrument’s exclusive MultiFlo™ technology provide the perfect choice for systems, processes and facilities that use a variety of gases, change gas types frequently or need to re-range while preserving gas measurement and control accuracy. It enables a new level of process flexibility combined with unprecedented flow measurement and control performance.

Most popular related searches

mass flow control

thermal mass flow meter

thermal mass flow control

thermal mass flow

mass flow metering

mass flow meter

mass flow

flow control

flow meter

gas delivery system

- Programmable multi-gas/multi-range capabilities

- Brooks® MultiFlo™ gas database contains thousands of native gas runs to establish correction functions

- Sub-1 second flow response time and accuracy of 1% set point for demanding applications

- Well suited for a variety of gases

- Fast response, Hastelloy sensor

- Easily accessible diagnostic service port is independent of tool communication

- Multi-protocol communication options include DeviceNet™, EtherCAT®, Profibus® and RS-485 analog interface

- MultiFlo™ technology enables new gas calibrations and full-scale ranges without removing the MFC from the gas line, maximizing process uptime

- MultiFlo™ programming is simple and user-friendly; new gas can be selected in under 60 seconds

- OEMs and large end users can greatly reduce the number of gas and range-specific controllers they inventory

- Excellent process gas accuracy backed by superior metrology systems and calibration based on global standards

- Corrosion-resistant sensor provides unmatched long-term stability ensuring maximum yield and throughput

- User-accessible service port simplifies troubleshooting and diagnostic tasks

- Variety of elastomer seals provide cost performance flexibility across range of applications

- Multi-protocol communication interface supports integration into existing systems

- Solar cell chemical vapor deposition systems

- Life sciences bioreactors

- Vacuum processes

- Nanotechnology/MEMS fabrication

- Plasma, glass and web coating systems

- Excellent option for manifold/gas delivery systems