- Home

- Companies

- MSE Filterpressen GmbH

- Products

- MSE Filterpressen - Hot Filter Press

MSE Filterpressen - Hot Filter Press

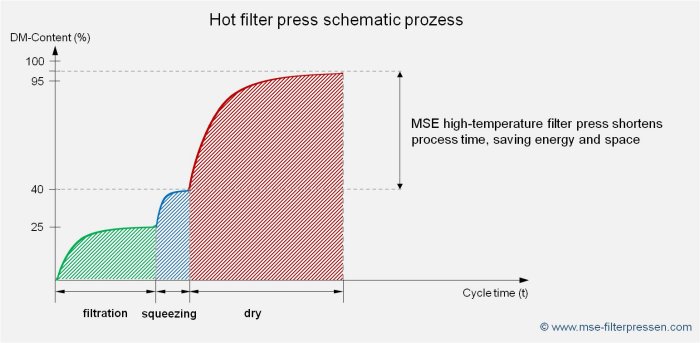

The hot filter press combines the standard process steps of a membrane filter press, (filtration, filter cake washing and squeezing), with the additional function of a thermal filter cake drying (TCD). As a result, all process steps are carried out in one plant, the hot filter press. Dewatering and drying of the resulting filter cake is thus done without a downstream drying process. Cost-intensive and time-consuming vacuum contact drying is therefore no longer necessary.

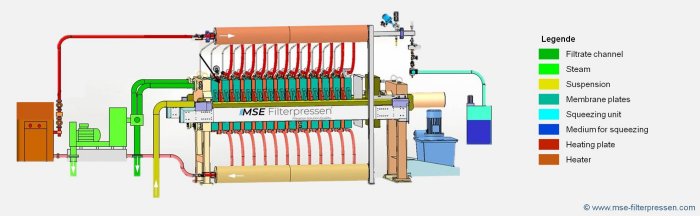

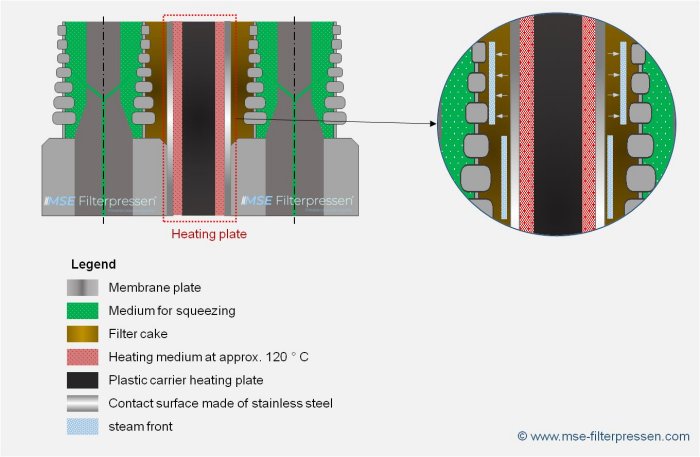

In the basic version, the technical design corresponds to a conventional filter press with a plate pack of membrane plates. Filtration, washing and pressing out are carried out as usual. In contrast to the conventional method, the system consists of membrane filter plates and heat exchanger plates, which are installed alternately in a filter press (see illustration). For thermal drying, hot steam and/or oil is applied to the working space behind the membrane and the filter cake is thermally dried accordingly. The advantage of this process is that a high dry matter content (DM content) of over 90% is achieved. On the one hand, the combination of membrane filter plate and heating plate reduces energy and dewatering costs at comparatively low procurement costs. On the other hand, experience has shown that it guarantees low residual moisture in the filter cake. Further information on the description of the high-temperature filter press can be found in the following press article.

The heating plates with heat exchangers consist of a plastic carrier coated with V4A stainless steel on the contact surfaces for heat transfer. The use of this material combination therefore allows for filtration and washing via the heating plate. After the filter press has been completely fed with the process medium, the resulting filter cake is pressed against the heat exchange plate using membrane technology and the heat exchange plates are subjected to saturated steam up to 120°C in a further process step. The steam front forming on the contact surface due to the rapid heat transfer escapes through the filter cake and removes the pore water still contained in the solid.

- Filtration and thermal drying in one machine

- High dry matter content in the filter cake can be realized

- Saving of downstream drying processes / drying systems and thus comparatively low investment costs

- Shorter cycle times, reduced drainage costs and low specific energy consumption