- Home

- Companies

- Maag Witte GmbH

- Products

- Maag Witte - Model POLY-AT - Discharge ...

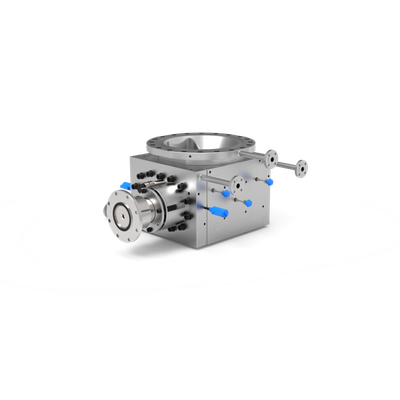

Maag Witte - Model POLY-AT -Discharge Gear Pumps

The POLY-AT design offers exceptional flexibility when it comes to installations beneath the polymer melting reactor. Customers can choose from three different flange geometries to ensure they are always benefiting from the best combination of reactors and pump flanges from both a technical and economical perspective. The new gear geometries facilitate differential pressures of up to 320 bar for selected pump sizes. What’s more, the new design is rounded out with the usual variety of different material combinations. The most common of these combinations has to be a stainless-steel or carbon-steel housing with tool steel or aluminium-bronze friction bearings.

The result is a redesign that impacts on all core components: friction bearings, housings and gear shafts have all been modified. From a technical perspective, this has meant real advantages in terms of conveying properties and product qualities thanks to the reduced heat input, lower shear and shorter dwell times of the polymer in the smelting reactor. What’s more, the optimised gear shafts and modified housing geometry facilitate significantly higher throughputs than with pumps of the same footprint in the previous design. This in turn allows for increases of up to 40% without changing the installation size.

- Lower bearing temperature, leading to lower stress on the polymer

- Optimised inlet geometry, leading to minimal pressure loss and therefore minimal dwell times of the polymer in the reactor

- Three different flange types each (EN 1092-1 or ANSI B16.5)

- Three different pressure versions (200 bar, 250 bar, 320 bar)

SX version:

- Flange geometry integrated in the housing

- Minimal installation space

MX version:

- Blind holes in flange

- Largest possible cross section

- Minimal pressure loss

- Ideally suited for highly viscous polymers

LX version:

- Flange with through holes

- Maximum flexibility for the installation

- Very low pressure loss

- Housing version

- Sealing technology

- Flange versions

- Pressure sensor

- Temperature sensors

Housing

- Pressure versions

- 200, 250, 320

- Flange versions

- SX, MX, LX

Features

- Sealings

- Viscoseal cooled /uncooled, stuffing box heated/unheated

- Temperature monitoring

- Bearings and Housing

- Pressure monitoring

- Suction and differential

Flanges

- Flange versions

- EN 1092-1 or ANSI B16.5

Applications

- Medium/Fluids

- PP, PET, ABS, PA, EPS, Elastomere, PC

- Lower bearing temperature, leading to lower stress on the polymer

- Optimised inlet geometry, leading to minimal pressure loss

- Minimal dwell times of the polymer in the reactor

- Three different flange types each (EN 1092-1 or ANSI B16.5)

- Three different pressure versions (200 bar, 250 bar, 320 bar)

- Larger viscosity range

- Simplified handling thanks to lower weight

- Increased throughput of up to 40% without changing the installation size

- Lower shear

- Improved product quality

- Reduced heat input

- Simplified spare part management thanks to the use of identical components for all series

The POLY-AT series (on the right) offers a much larger suction flange compared to the classic design. As a result, the dwell time of the polymer is reduced and the throughput at the same installation dimension can be significantly increased.

POLY pumps in classic design can easily be replaced with a POLY-AT with the previous smaller installation size but with the same throughput.