- Home

- Companies

- Baioni Crushing Plants Spa

- Products

- Baioni - Model BaiPod - Skid-mounted ...

Baioni - Model BaiPod -Skid-mounted Centrifuge System

BaiPod, the new compact dewatering unit complete with all equipment readily installed for a complete dewatering plant and to process a wide range of sludges. Its unique design and compact construction concept, the BaiPod is easily transportable and is particularly suitable to meet season demand, cover during maintenance or as part of a disaster recovery program following a major breakdown, with a competitive rental cost. The client has a full sludge dewatering plant with all the necessary equipment and peripheral components able to assure instant operation. It is a skid-mounted unit, the compact design allows easy transport, small footprint and high performance during the whole length of the process.

Commissioned and tested with overall success abroad, the Environment Division of Baioni Crushing Plants launches the lastest BaiPod, the new compact dewatering unit complete with all equipment readily installed for a complete dewatering plant and to process a wide range of sludges.

With its unique design and compact construction concept, the BaiPod is easily transportable and particularly suitable to meet season demand, cover during maintenance or as part of a disaster recovery program following a major breakdown, with a competitive rental cost. The client has a full sludge dewatering plant with all the necessary equipment and peripheral components able to assure instant operation.

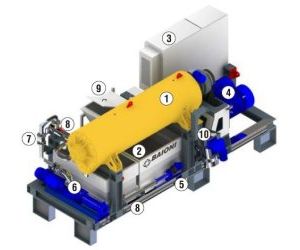

- BAIDEC 47L or 62L Decanter Centrifuge in AISI 304 or Duplex (on demand).

- Control panel with PLC logic, touch-screen operation, weather-tight and cooled.

- Feed pump and polyelectrolite dosing pump, both PLC operated via frequency inverters.

- Dry dosing and mixing system with a low level 100 kg feed hopper (BASF™).

- Automatically operated wash-out valves for water and sludge.

- Flowmeter for sludge and polymer feed.

- Short screw conveyor for solid cake (additional longer screw conveyor can be fixed). •All water plumbing, connections and a sturdy supporting steel frame.

- Single/twin motors.

- Collection tank and pump for centrate.

- Legs extensions, 500 mm.

- Extra screw conveyor for solid cake (3000 mm length).

- Insulated box with hinged doors and inspection portholes.

- Oil heating unit for extremely cold environments (box required).

- BAIDEC decanter

- Polymer dosing system

- PLC control system

- Motors

- Polymer dosing pump

- Feed pump

- Flowmeter

- Agitators

- Polymer mixing system

- Screw conveyor

- No capital expenditure

- Ideal solution of "pay for use"

- No increased costs for maintenance

- Max. flexibility

- Little operator attendance

- On-going support and assistance

- Custom service

- Municipal waste water sites

- Aggregates and mineral processes

- Oil refineries

- Sewage waste water sites

- Food processing plants

- Quarry recycling applications

- Soil washing

- Lagoon emptying and cleaning

- Construction sites