- Home

- Companies

- Yokogawa Fluid Imaging Technologies, ...

- Applications

- FlowCam for Materials - Materials - ...

FlowCam for Materials - Materials - Advanced Materials, Fibers, and Polymer Characterization - Manufacturing, Other

Effective particle analysis techniques are essential to quality control programs across a wide range of manufacturing industries. FlowCam offers a complete solution for characterizing particles, ensuring end-product quality and conformity with industry regulations.

Most popular related searches

particle analysis

particle imaging

ASTM standard

wash water

particle characterization

particle sizing

compliance performance

particle monitoring

process analysis

material characterization

Use FlowCam to:

- Perform compliance testing in accordance with ISO and ASTM standards

- Enhance quality assurance programs by monitoring particle uniformity and consistency throughout the production process

- Determine filter performance by comparing image and concentration data pre and post-separation

- Evaluate quality of raw materials as inputs into manufacturing processes

Enhance Particle Analysis and Characterization with Digital Images

FlowCam is a comprehensive dynamic imaging analysis platform that provides an efficient method to confirm data obtained from other particle analysis techniques.

With real digital images, you can verify the size, shape, and identity of your particles.

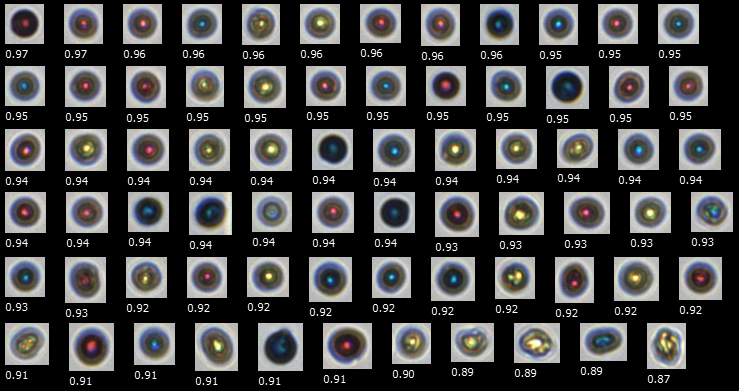

- Confirm size, shape, circularity and material uniformity for printer toner and polymer characterization during and after production.

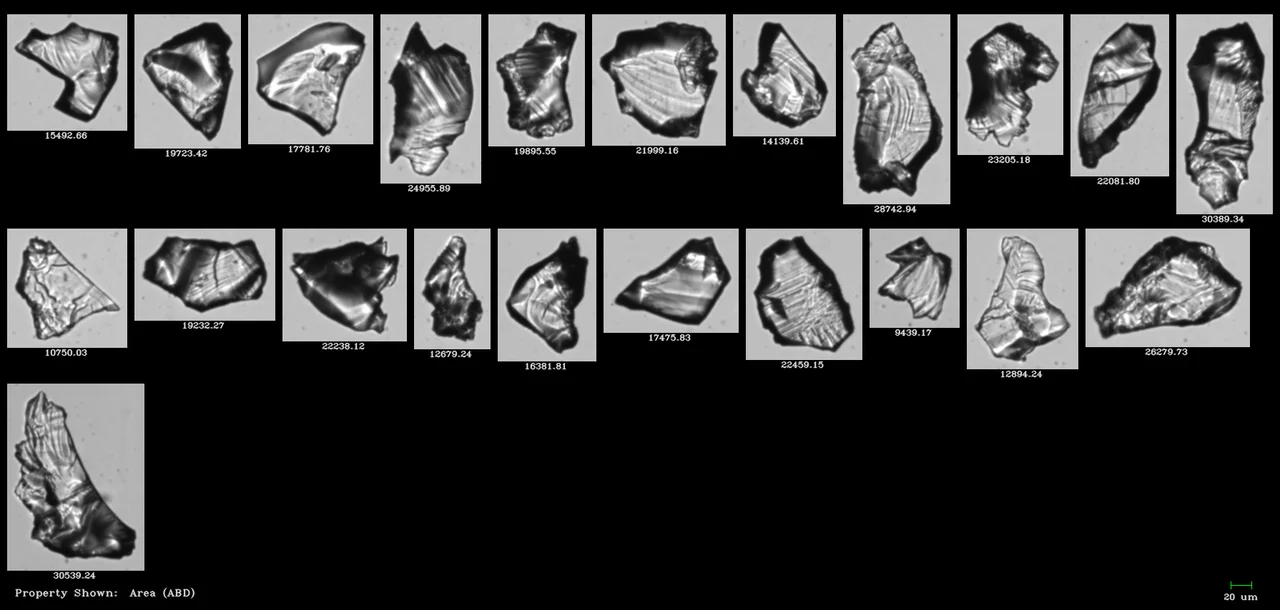

- Evaluate size and shape uniformity of superabrasive particles such as micronized diamonds and cubic boron nitride (CBN).

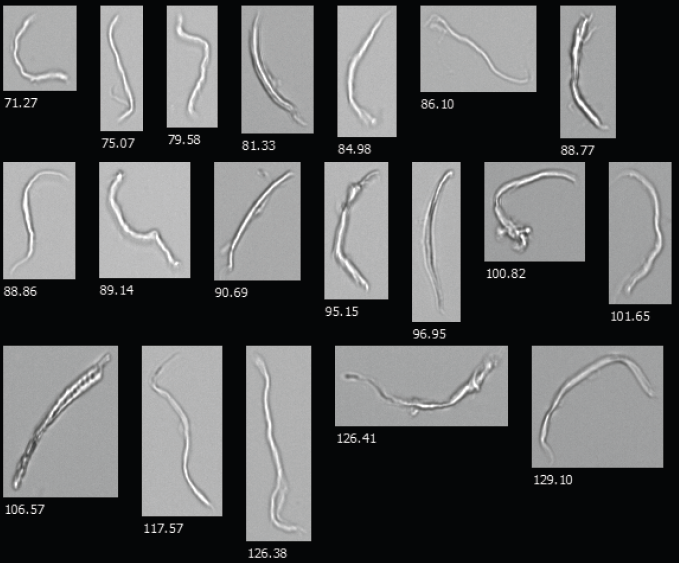

- Compare material properties across processing stages using parameters specifically designed to accurately measure fiber morphology.

- Validate wash water cleanliness and visually confirm, quantify, and characterize each particle type.

Stay in the loop!

Select your areas of interest to receive industry updates.