Potential Engineering products

Mechanical Screens

Potential - Step Screen

Potential Engineering Step Screens, engineered for unparalleled efficiency in waste separation and collection. Utilizing a unique configuration of mobile and fixed lamellae, these screens systematically lift and capture screenings, expanding the filter surface to capture even the finest particles. With a compact size, ease of operation, and cutting-edge features like pulling and cutting mechanisms, our screens redefine the standards of wastewater filtration, offering a reliable solution for waste management challenges.

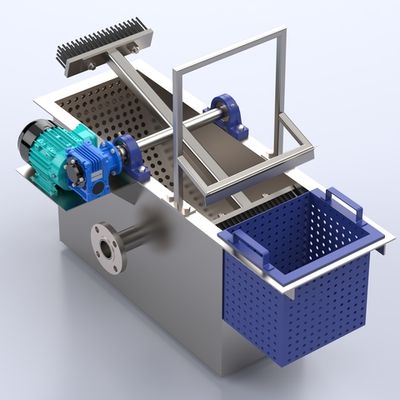

Potential - Honeycomb Screen

Honeycomb screens are widely deployed at the entrance of the hydraulic structure, water intake, and pumping stations to trap flowing Debris that could instigate downstream trouble. The flat wire belt finds application in industrial, municipal, and process water screening. The inclined honeycomb belt rotates at a constant speed, arresting Debris; it works with the help of a motor and gearbox. The Debris on the Honeycomb screen is scraped using water jet spray and brush. The unique feature of the screen is that it is pivot-mounted and can be turned to a horizontal position for maintenance. The screens can be equipped with an overload protection device and a conveyor.

Potential - Multi Rake Bar Screen

Multi Rake Bar Screens are widely deployed at the entrance of the hydraulic structure, water intake, and pumping stations to trap flowing debris which can instigate downstream trouble. These mechanical bar screen designs perfectly serve industrial, municipal & process water screening. These are most favorable for high solid loads. The equally spaced inclined bars arrest the debris. The cleaning element consists of a comb, screwed to the drive chain. The chain is with an optional overload protection device. The screen can also be equipped with a conveyor.

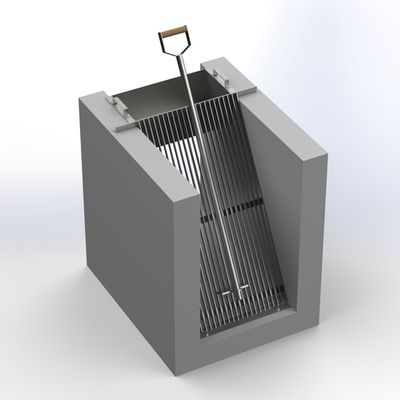

Potential - Manual Bar Screen

Manual Bar Screens are widely deployed at the entrance of the hydraulic structure, water intake, and pumping stations to trap flowing debris of large & medium sizes that could instigate downstream trouble. These screens are suited to serve industrial, municipal, and process water/wastewater screening. The debris is arrested in equally spaced inclined bars and is cleaned manually with the help of a manual rake comb, provided with the screen. We manufacture fixed and removable manual bar screens.

Potential - Basket Screen

The basket screen is a coarse bar screen, installed in pumping stations and manholes. The basket is lifted and lowered in a desired path guided by rails via an electric hoist. The rails are shaped in the upper area which facilitates emptying of the basket. The basket is constructed of stainless steel sections with a gap of 10 – 40 mm. When the screen basket is raised, the feed is automatically blocked by a drop screen so that no screenings can get into the outlet channel while the basket is being emptied. As a leading basket screen manufacturer, Potential Engineering provides reliable solutions for wastewater treatment.

Potential - Rotary Brush Screen

The Rotary screen is manufactured from stainless steel and is designed to remove fiber, hair, and other foreign objects from a waste stream. It uses a static stainless steel perforated semi-cylindrical screen bed for this purpose. A stainless steel armature with brushes continually cleans this bed. The rotary brush is selected based on the particular waste, and the screen bed is gently swept. This action cleans the screen bed but puts no pressure on the screen bed. This prevents the distortion and wear that can occur on other types of perforated fine screens. The brushes are cleaned by a stainless steel scraper blade and discharged outside the machine.