- Water & Wastewater - Biological Treatment

- Water & Wastewater - Water Clarification

- Water Technologies - Cooling Tower Components

- Water Technologies - Lamella Clarifiers

- Water Technologies - Media for Biofilm Processes

- Stormwater Management

- Polychem® - Water and Wastewater Components

- Water & Wastewater - Polychem® - Packages

- Water & Wastewater - Polychem® - Components - Sprockets

- Water & Wastewater - Polychem® - Components - Drive Unit Assembly

- Water Technologies - Mass Transfer Components

- Water Technologies - Components for Aquaculture / Fish Farming

- Water Technologies - Components for Agricultural Engineering

- Cooling Tower - Film Fills - Cross-Fluted Fills

- Cooling Tower - Film Fills - Herringbone Fills

- Cooling Tower - Film Fills - Offset-Fluted Fills

- Cooling Tower - Film Fills - Vertical-Fluted Fills

- Cooling Tower - Film Fills - Hybrid-Fluted Fills

- Cooling Tower - Film Fills - Fill Supports

- Cooling Tower - Trickle Fills

- Cooling Tower - Splash Fills - Modular Splash Fills

Brentwood Industries, Inc. products

Water Technologies - Cooling Tower Components

PLASdek - Model NET 150/ FC20.30/ FC70.34 - Splash and Trickle Fills

Our Splash and Trickle Fills have been specially designed for medium to strongly polluted cooling water, the focus of the development being on a high stability as well as on easy and economical installation. Therefore these fills are built from mechanically joint grids and are easily cleaned.PLASDEK - Model NET 150 / FC20.30 / FC70.34 - Splash and Trickle Fills

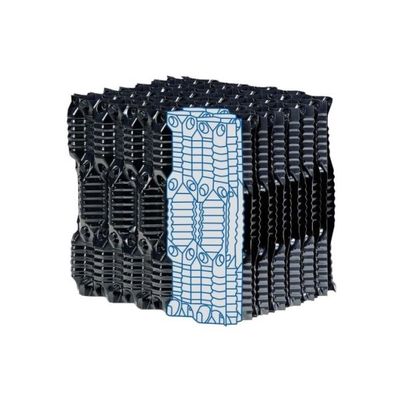

Our Splash and Trickle Fills have been specially designed for medium to strongly polluted cooling water, the focus of the development being on a high stability as well as on easy and economical installation. Therefore, these fills are built from mechanically joint grids and are easily cleaned. The NET 150 grid packings are high-performance fills which provide an optimized pressure drop. We offer a unique flexibility in measures for this fill type. 8y using various materials, for example flame-retardant Polypropylene (PP), high-temperature PP or the special SANIPACKING* PP, the NET 150 grid can be adapted to a wide range of requirements.PLASdek / CLEANdek - Model KBC 320 / KVC 319 - Vertical Flow Fills

PLASdek and CLEANdek vertical flow fills are designed for the use in counterflow cooling towers with poor water quality. With different types in PP, PVC and PPHT and different material thickness, our fills cover all customer requirements. Fill media in flame retardant or anti-bacterial types are available on request. 8earing capacity and weight/m1 depend on sheet thickness. It will be selected according to customer specification in consideration of process conditions and safety factors for temperatures, lifetime and material properties. Our experts recommend solutions for the support structure on request.Model SPN - Cone Spray Nozzles

The axial nozzles are designed as complete cone spiral nozzle consisting of a casing and an insert. Correctly assembled, the nozzles distribute the water with a spray angel of 120 degrees, where the water flow rate depends on the operational pressure. We recommend checking the operation conditions, as nozzle distance and height have to be chosen according to the respective plant requirements.

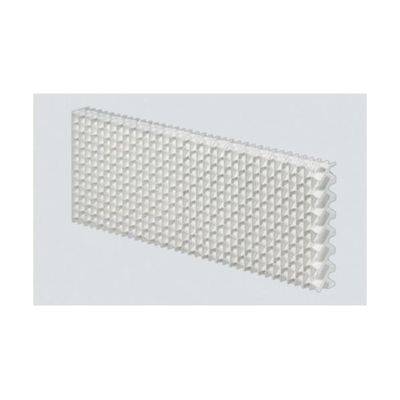

PLASdek - Model KFP 319 / KZC 312 - Cross-Fluted Fills

In the manufacturing process we developed the foils are reinforced at the outer edges and in the middle and are therefore very stable. This makes our film fill media extraordinarily resistant to erosion. Our unique welding method connects the single foils with up to 20.000 welding points per m3. This high number of connections results in robust packings with high mechanical load capacity. Bearing capacity|and weight/m3 depend on sheet thickness. It will be selected according to customer specification in consideration of process conditions and safety factors for temperatures, lifetime and material properties. Our experts recommend solutions for the support structure on request.

PLASdek - Counter-Flow Cooling Tower Fills

Different Types For All Requirements – Available In PVC And PP; From small cooling towers to large cell and natural draught cooling towers: Our PLASdek packings fulfill all requirements. Different types of film fills with large specific surface are highly suited for clean and medium water qualities, whereas for special operation conditions and for strongly polluted water grid structures are the best choice. Ask our experts. They have long time experience and will be grateful to help you choose the right fill for your application.

Fills and Nozzles for Cross-Flow Cooling Towers

Optimal heat transfer properties; low pressure drop; Generally, every cross fluted fill could be cut to be installed in a cross-flow cooling tower. Such a fill, however, would not perfectly fit the requirements; we therefore developed a special range of fill for this type of tower (FX12.12 or KSN with a drift eliminator section KSA and air inlet louvre section KSB).Drift Eliminators

In all different types of cooling towers drift eliminators are used to reduce the loss of water and emissions. Above the water distribution and the cooling fills, a layer of drift eliminators is installed for this purpose. It catches the water drops which are carried away with the air flow and redirects them into the cooling water circuit.