- Natural Resource Processing - Tabor Vibrating Screens

- Natural Resource Processing - CSI Screen Scroll Centrifuges

- Waste Management - Vertical Cuttings Dryer

- Waste Management - Hyper-G Shale Shakers

- Waste Management - OEM Composite Shaker Screens

- Waste Management - Turn-Key Waste Cuttings Treatment System

- Biofouling Solutions

- Clarification

- Coarse Filtration

- Fine Solids Separation

- Reverse Osmosis Systems

- Mining Equipment

- Oil and Gas Products

- Screen Cleaning Systems

- Waste Management

- Trenchless/Construction

- Small Hydro Intake Equipment

- Dredge Dewatering

- Water Intake

- Custom Fabrication

- Storm Water Coandas

- Storm Water Filtration

Elgin Separation Solutions products

Natural Resource Processing - Tabor Vibrating Screens

Elgin - Tabor Horizontal Vibrating Screen

A mainstay in coal prep, magnetite recovery, and dewatering, the high-performance Tabor Horizontal (TH) Vibrating Screen delivers rock-solid dependability. It’s ideal for environments with high production volume but limited space, and is available in single, double, and triple decks. With rugged construction and smart customization options, it gives you everything you need for worry-free work.

Natural Resource Processing - CSI Screen Scroll Centrifuges

CMI - Vertical Screen Scroll Centrifuge

The CMI Model EBR/EBW Vertical Screen-Scroll Centrifuges are designed for small particles and will provide efficient and consistent moisture reduction even with fluctuating feed rates. Commonly used with a continuous process in which slurry containing both solid and liquid is continuously fed into and continuously discharged from the centrifuge. In a typical screen scroll centrifuge, the basic principle is that entering feed is separated into liquid and solids as two products. In a typical screen scroll centrifuge, the basic principle is that entering feed is separated into liquid and solids as two products. The feed is transported from small to larger diameter end of basket by the inclination of the screen basket and slightly different speed of the scraper. The solid material retained on the screen is moved along the cone via an internal screw conveyor while the liquid output is obtained due to centrifugal force causes the feed slurry to pass through the screen openings.

Waste Management - Vertical Cuttings Dryer

Elgin - Vertical Cuttings Dryers

Elgin’s CSI™ E-Series Vertical Cuttings Dryers are the next evolution of the industry leading CSI-04™ and CSI-03™ VCD’s. The new CSI–E3 Cyclone™ Vertical Cuttings Dryer is designed with an improved oil-sealed gearbox drive unit that requires no active lubrication system for operation. More importantly, the new gearbox design provides for improved dryer performance when compared to their predecessors. Elgin’s CSI Cyclone™ E-Series eliminates active system lubrication components while increasing G-force and speed performance.

Waste Management - Hyper-G Shale Shakers

Elgin - Shale Shaker

With the introduction of Elgin’s Hyper-G™ shaker in 2012, sticky reactive solids became manageable utilizing Elgin’s dual-motion, variable speed vibrator motor configuration that is fully adjustable during operation without having to shut down. Patented ‘Water-Fall’ screen system design dramatically reduces the potential for solids bypass typically encountered by damaged screen gaskets, improper installation, and flooding of the rear screen by fluid.

Whether you are looking for a three-panel, four-panel or six-panel screen deck design, Elgin’s Hyper-G features the highest screening surface area on the market today.

Waste Management - OEM Composite Shaker Screens

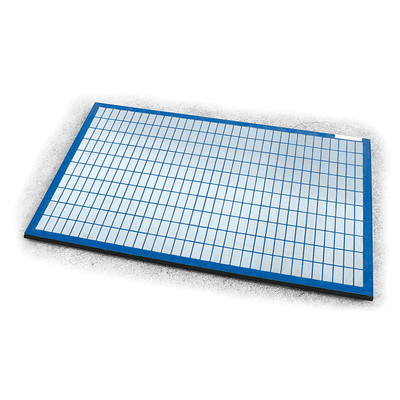

Elgin BlueCrest - Composite Shaker Screens

Composite Polyurethane Technology – BlueCrest™ composite screens are constructed using a rigid steel frame and perforated plate; in which layers of woven wire cloth are bonded with powder-coating. New manufacturing technology has advanced shaker screen construction using composite material with steel reinforcement. These changes increase strength, longevity, and performance.

Performance – Elgin®’s BlueCrest™ composite shaker screens provide higher surface tension. The heating process causes the wire mesh to contract and provide for a tighter surface tension. The higher the surface tension, the longer lasting the screen. This means that higher flow rates with more viscous drilling fluids can be managed.

Waste Management - Turn-Key Waste Cuttings Treatment System

Elgin - Turn-Key Cuttings Waste Management System

Elgin’s CSI Cyclone™ Fully-Integrated, Turn-Key Vertical Cuttings Dryer (“VCD”) Packaged System is the industry’s most sophisticated waste solids management system available. This system has been designed to reduce drill cuttings and waste solids moisture by 90%. This allows operators to recover thousands of gallons of drilling fluid and/or water, that would normally have been disposed of, with the waste cuttings. Capable of processing oil-based and water-based waste cuttings without the need for a conversion kit. The perfect solution for clay-based drill cuttings.

Biofouling Solutions

Jacquelyn - Permanent Metal Coating

Jacquelyn (U.S. Patent #5,945,171) is a permanent metal coating that prevents zebra mussels and other biofouling. Because it does not rely on copper leach, it is both safe for the environment and long lasting, with a 15 year service life.

Clarification

Water Dissolved Air Flotation Units

Elgin Water Dissolved Air Flotation units are effective and efficient because they have better design features than competitive DAF systems. Every feature, from the overall geometry to the injection point is engineered for maximum efficiency. The result is a small, efficient, and simple to operate DAF unit.

Coarse Filtration

Coanda Sieve Boxes for Waste Stream Filtration

Coanda Sieve Boxes are used to eliminate debris larger than fine sand from a waste stream. The systems require low maintenance, using overflowing water and gravity to stay clean. We offer better material, using precision TIG welded wedge wire and a better hydrodynamic design to deliver an efficient and low maintenance system.

Fine Solids Separation

Decanter Centrifuges

Elgin Water has designed and manufactures a complete line of decanter centrifuges capable of achieving a hydraulic capacity of 500 gallons per minute. Made from 304 Stainless Steel and using only premium motors, bearings, and electrical components, Elgin’s waste management centrifuges are designed to perform in the most rigorous environments.