Advanced Cyclone Systems, S. A. (ACS)

- Home

- Companies

- Advanced Cyclone Systems, S. A. (ACS)

- Applications

- Emission control solutions for glass ...

Emission control solutions for glass and ceramic furnaces sector - Glassware

Glass and ceramic furnaces are typically associated with emissions of very fine particles (less than 5µm) in combination with high temperatures and load. An increasingly higher number of furnaces are powered with biomass fuel, further raising the level of particulate emissions that need to be treated, in order to comply with stricter regulatory limits. Solving this problem may or not require a two stage dedusting system such a cyclone pre-separation system followed by an ESP. Client`s needs frequently include a very high efficient dedusting system, robust enough to operate at high temperatures and to handle glowing particles.

Most popular related searches

emissions control system

particulate emissions

furnace

cyclone system

emissions regulations

emissions control

glass industry

cyclone separator

glassware

process emissions

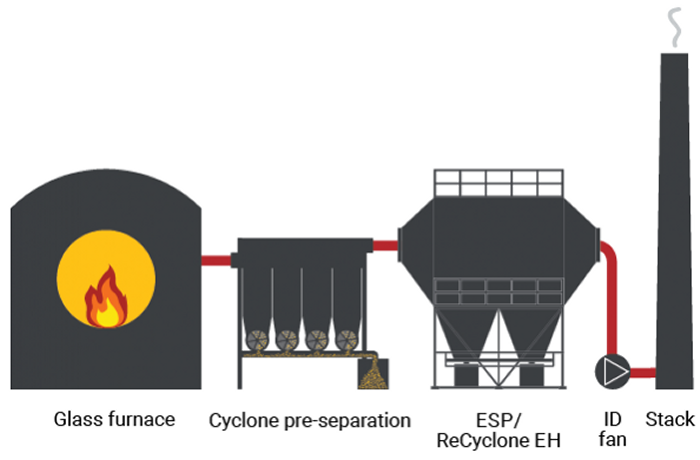

Glass and Ceramic Furnaces - General Arrangement

The general arrangement of a Glass making industrial line typically includes a Natural Gas furnace followed by an ESP as the End Stage Deduster. Changing to biomass fuel increases the level of particulate emissions that need to be removed before the stack (< 5µm).

The solution for this cases needs to be a two stage dedusting system that uses in a first step a cyclone system to remove a large quantity of the particles and the glowing particles (Hurricane) and a second stage for the fines (ESP or ReCyclone System), so to comply with the more stringent emissions regulations.

Stay in the loop!

Select your areas of interest to receive industry updates.