Emission control solutions for steel and ferroalloys sector - Metal - Steel

Steel and ferroalloys manufacturing processes involve high temperature exhaust streams, often at more than 900ºC. Typically, the gas flows from the furnace (usually electric arch type) and goes into a gas conditioning tower to cool down below 200ºC so that it can be treated by a Bag Filter. It`s also common to have ESP´s as end dedusters that can be preceded by a multicyclone serving as pre-separators.

Client`s needs include a very robust dedusting system, either serving as end-stage collector avoiding the need to cool down flue gases, or considerably decreasing the loads of aggressive material to bag filters.

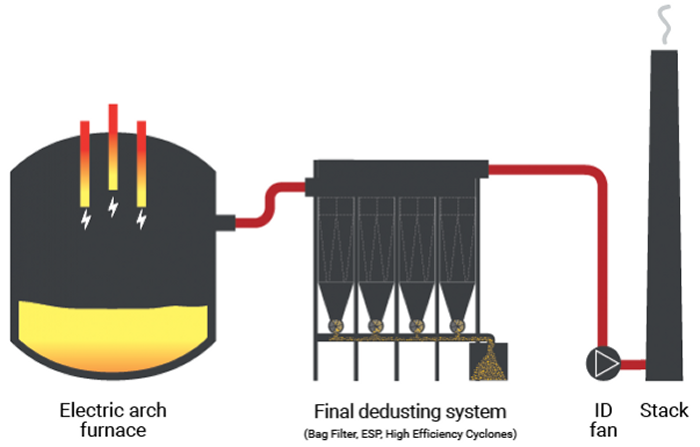

Steel and Ferroalloys (electric arch furnace) - General Arrangement

The general arrangement of a steelmaking or ferroalloy plant includes a gas conditioning tower to cool the gases to under 200ºC, upstream of a Bag Filter, or a multicyclone pre-separator, upstream of an ESP.

The Median Volume Diameter (MVD) of the particles coming from the exhaust gases of an electric arch furnace are typically very fine, ranging from 0.7µm to 1.3µm, with 65% under 1µm, for most ferroalloys (FeSi or CaSi).